Introduction

Occupational health and safety have become critically important in construction. Recently, the international construction industry has struggled with an increasing number of work-related accidents and other occupational health problems (

Xie et al. 2022;

Yu et al. 2019). The construction sector is a challenging place to work (

Powell and Copping 2010), as physically demanding tasks and harsh environmental conditions are common (

Aryal et al. 2017;

Fang et al. 2015;

Leung et al. 2016). Fatigue causes human error, and occupational fatigue is one of the principal causes of accidents (

Namian et al. 2018;

Techera et al. 2019;

Wong et al. 2019a). Occupational fatigue is an essential subject, as it may adversely affect an individual’s performance, safety, and health (

Bhuanantanondh et al. 2021;

Caruso 2014). In general, fatigue is multidimensional in terms of physical, mental, and cognitive aspects. Physical fatigue, after excessive workloads, reduces performance efficiency, whereas mental fatigue, resulting from intensive mental effort, reduces behavioral and cognitive performance (

Anwer et al. 2021;

Nwaogu et al. 2022).

Measurement tools should consider diverse aspects of workers’ fatigue for accuracy (

Anwer et al. 2021). Objective fatigue is widely understood as physical fatigue, and it can be measured quantitatively (

Jebelli et al. 2019b). Subjective fatigue is assessed qualitatively, and it indicates personal perception aspects, such as mental and cognitive fatigue (

Jebelli et al. 2019a;

Techera et al. 2018). The work environment in the construction field has dynamic and risky characteristics (

Fang et al. 2015). Characteristics such as changing and demanding schedules (

Chen et al. 2022;

Ferrada et al. 2021), project complexity (

Xie et al. 2022), climate effect (

Cheung and Zhang 2020), and long work hours (

Ibrahim et al. 2020;

Liu et al. 2020;

Powell and Copping 2010) affect individuals’ perceptions. As these perceptions cause the time lag between objective and subjective fatigue, quantitative measurements alone may produce inaccurate assessments (

Ferrada et al. 2021;

Riegler et al. 2021). Therefore, the evaluation of subjective fatigue is critical, particularly in the construction sector (

Powell and Copping 2010). Considering multiple aspects of fatigue reduces measurement errors and increases the reliability of the results (

Åhsberg et al. 2000b). However, research on multidimensional approaches in the construction field is scarce (

Anwer et al. 2021). Thus, to measure fatigue accurately, it is essential to establish a multidimensional evaluation tool.

Extant literature has investigated diverse methods to accurately measure occupational fatigue (

Bhuanantanondh et al. 2021;

Techera et al. 2018;

Xing et al. 2020). However, several limitations exist. First, self-reported methods, such as surveys, do not comprehensively measure workers’ physical fatigue. Second, although several measurements of objective fatigue have been attempted using a PC-based psychomotor vigilance task (

Aryal et al. 2017;

Techera et al. 2018), heart rate (HR;

Chang et al. 2009;

Zhang et al. 2019), and skin temperature (

Mehta et al. 2017;

Umer et al. 2020), their validity as physiological proxies was limited. Third, most previous experiments were performed in a laboratory and not a real-world setting (

Anwer et al. 2020;

Aryal et al. 2017;

Umer et al. 2020) or in a restricted simulation (

Lee et al. 2017;

Yin et al. 2019;

Zhang et al. 2019). Therefore, work environments should be evaluated both subjectively and objectively in a real-world setting to ensure ecological validity and reliable data collection.

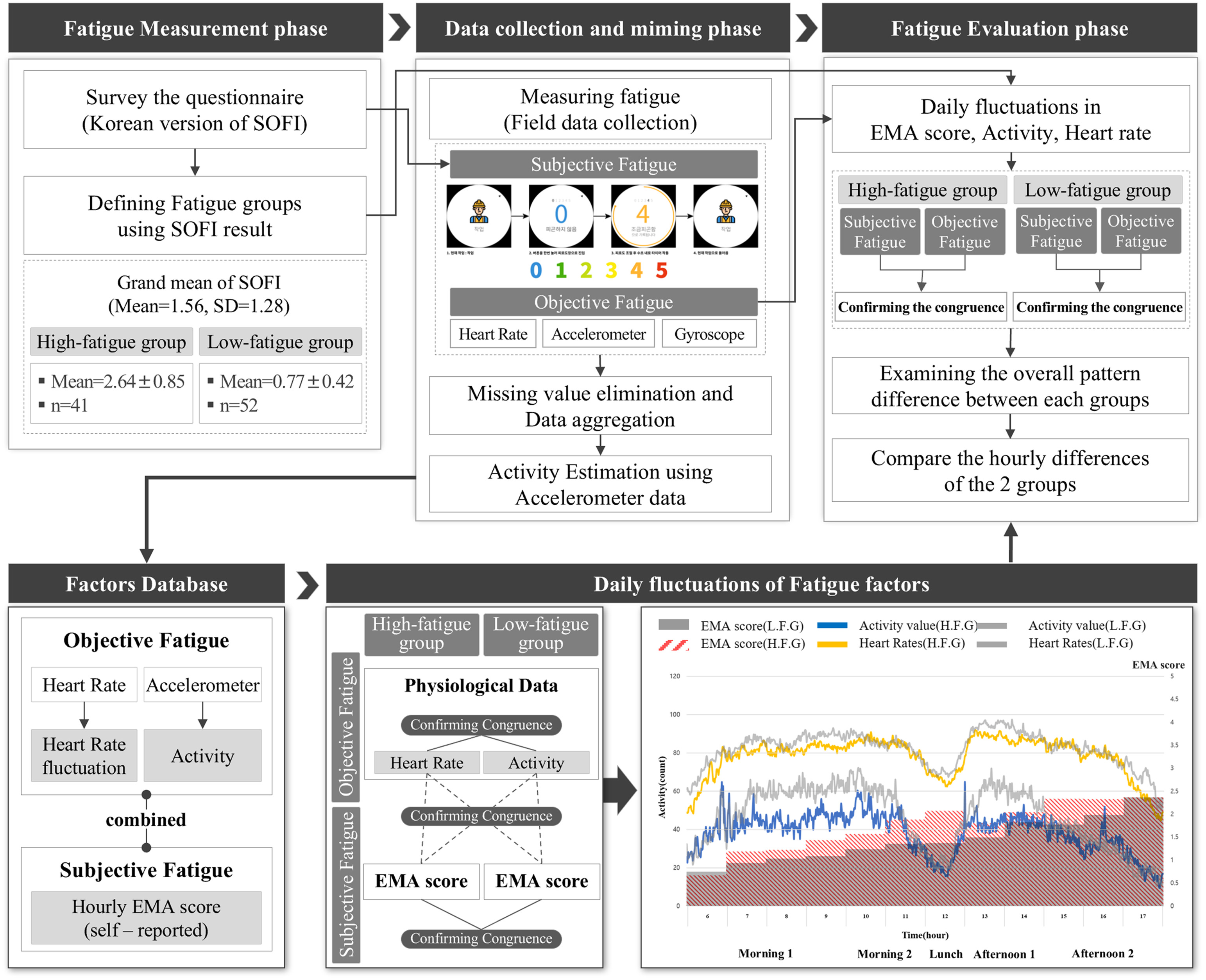

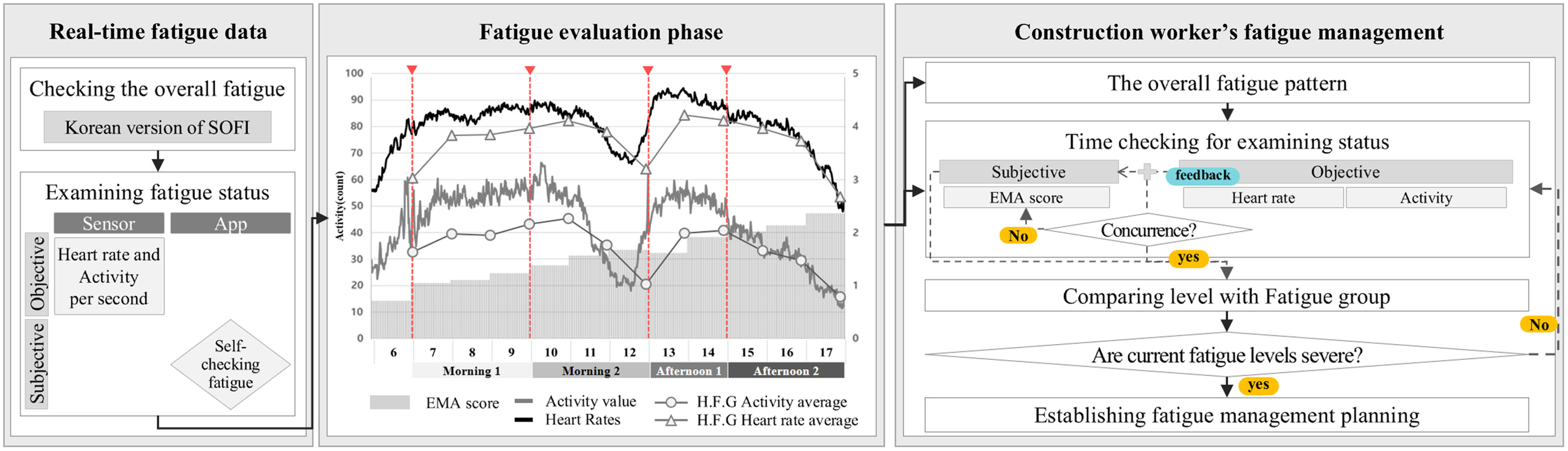

To address these gaps in knowledge, this study aimed to develop a framework using subjective and objective evaluation to measure construction workers’ fatigue in actual working environments in real-time. Specifically, this study (1) proposed a multidimensional objective and subjective fatigue measurement approach, (2) assessed construction workers’ fatigue levels and influencing factors in real field conditions, and (3) evaluated real-time fatigue measurements during construction workers’ working hours. The development of a tool to measure multidimensional fatigue utilizing a real-time approach in field conditions is expected to facilitate the management of worker safety by investigating differences and correlations between subjective and objective fatigue.

Conclusions

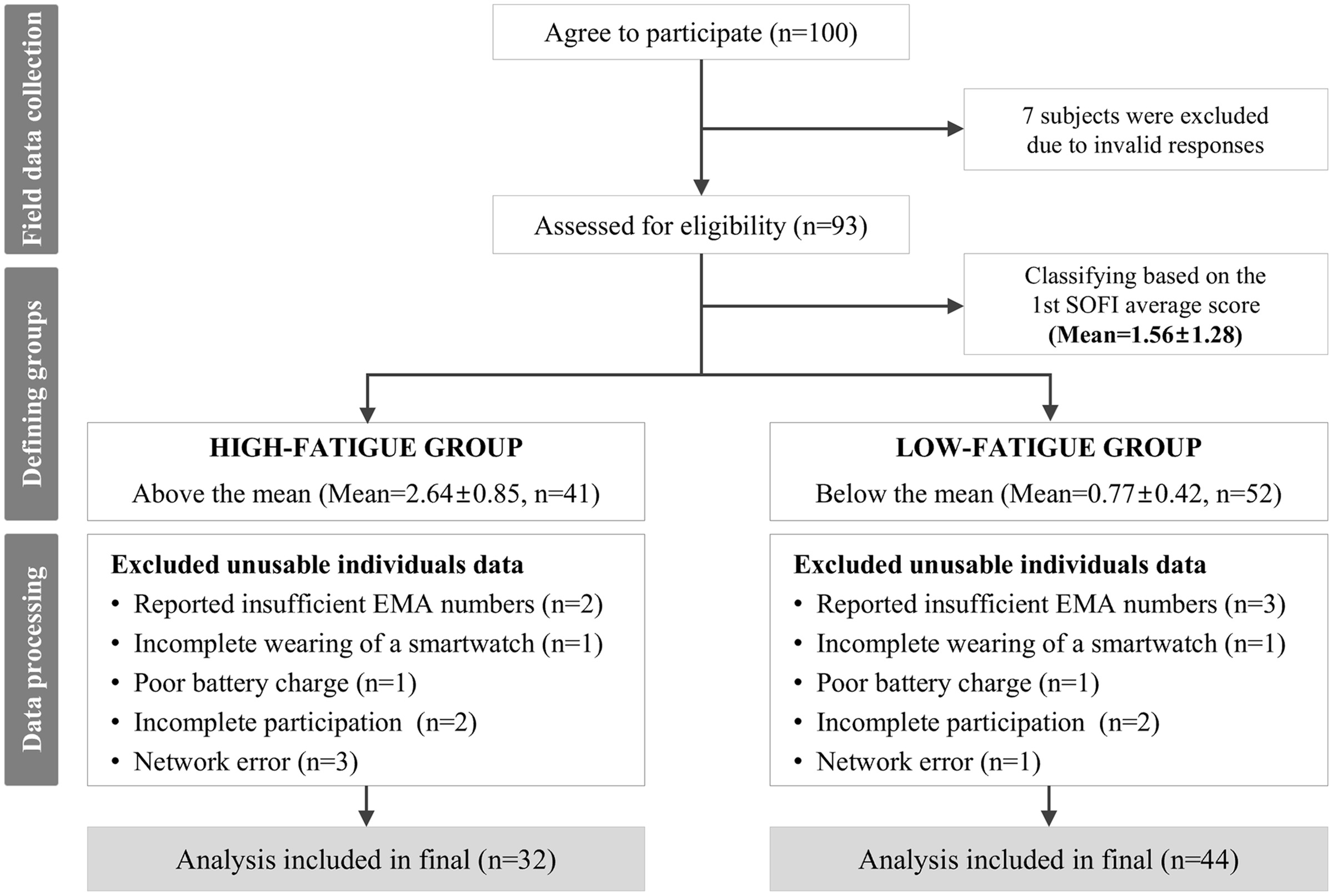

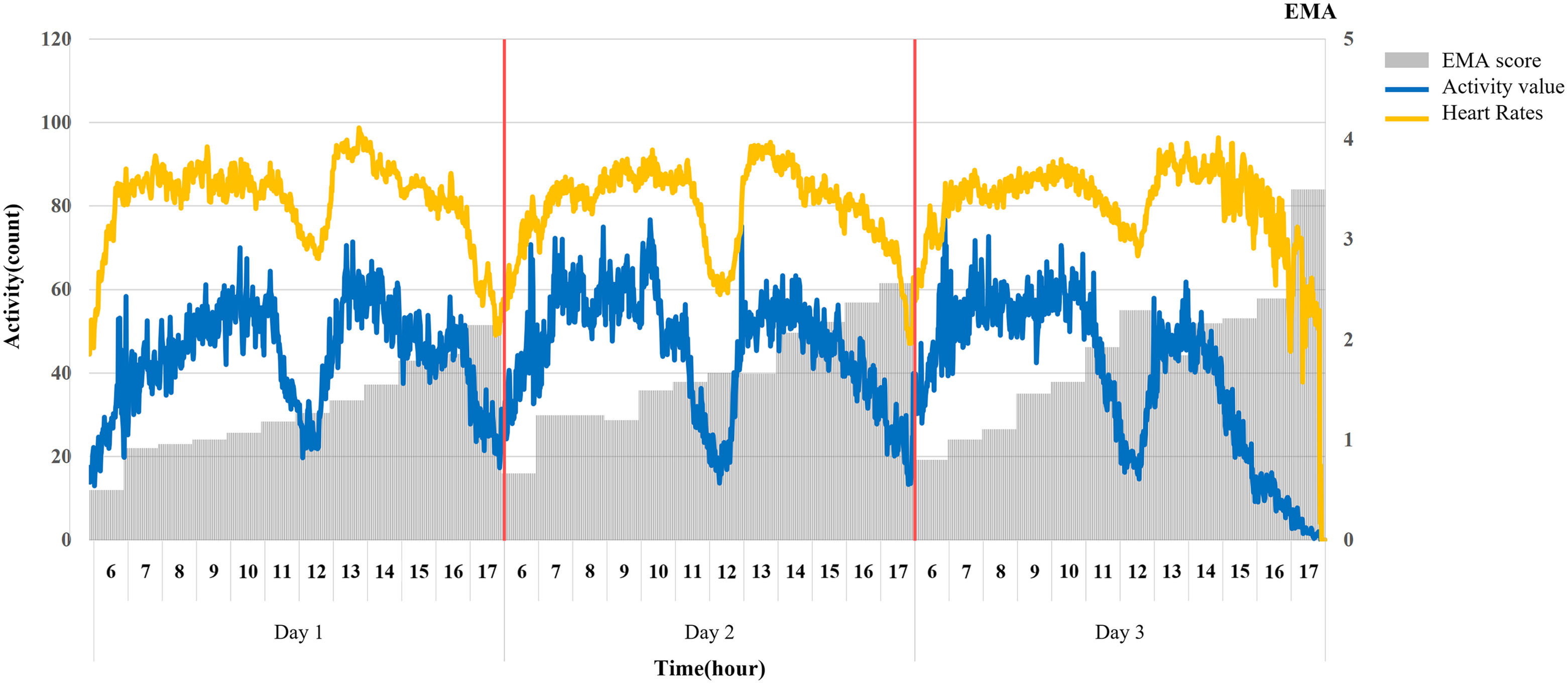

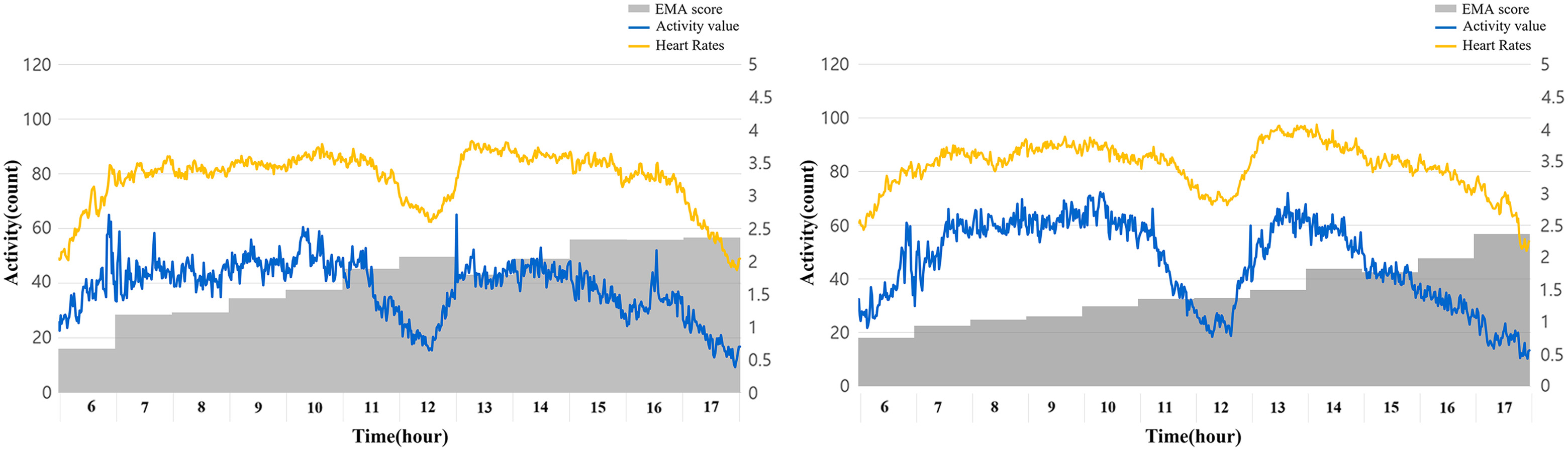

This study aimed to construct a real-time evaluation framework to measure and evaluate construction workers’ subjective and objective fatigue using EMA and smartwatches at construction sites. To validate the utility of the proposed framework, subjective and objective fatigue factors of 100 construction workers, who were divided into two groups, were observed over the course of three days.

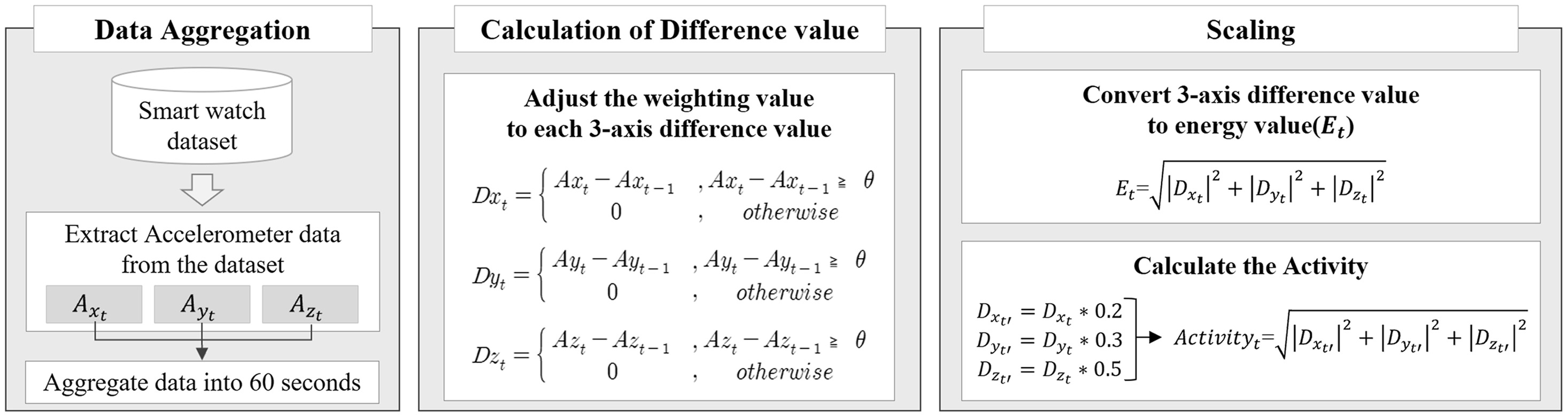

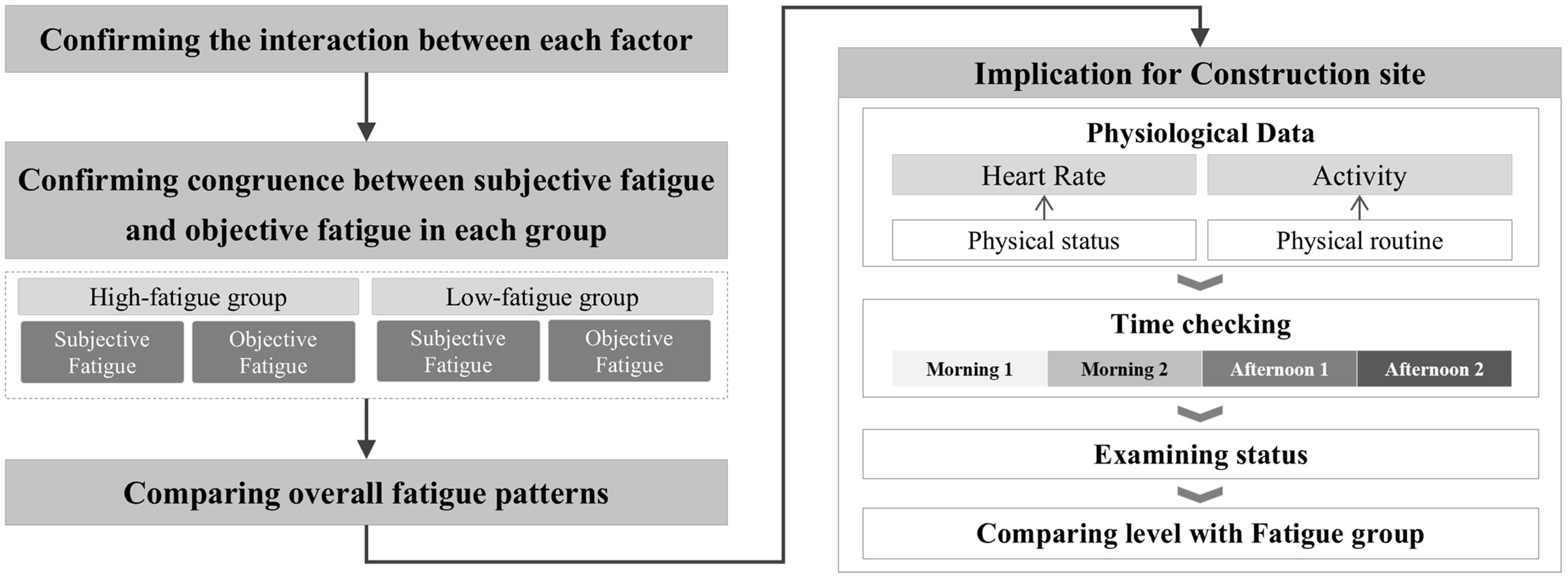

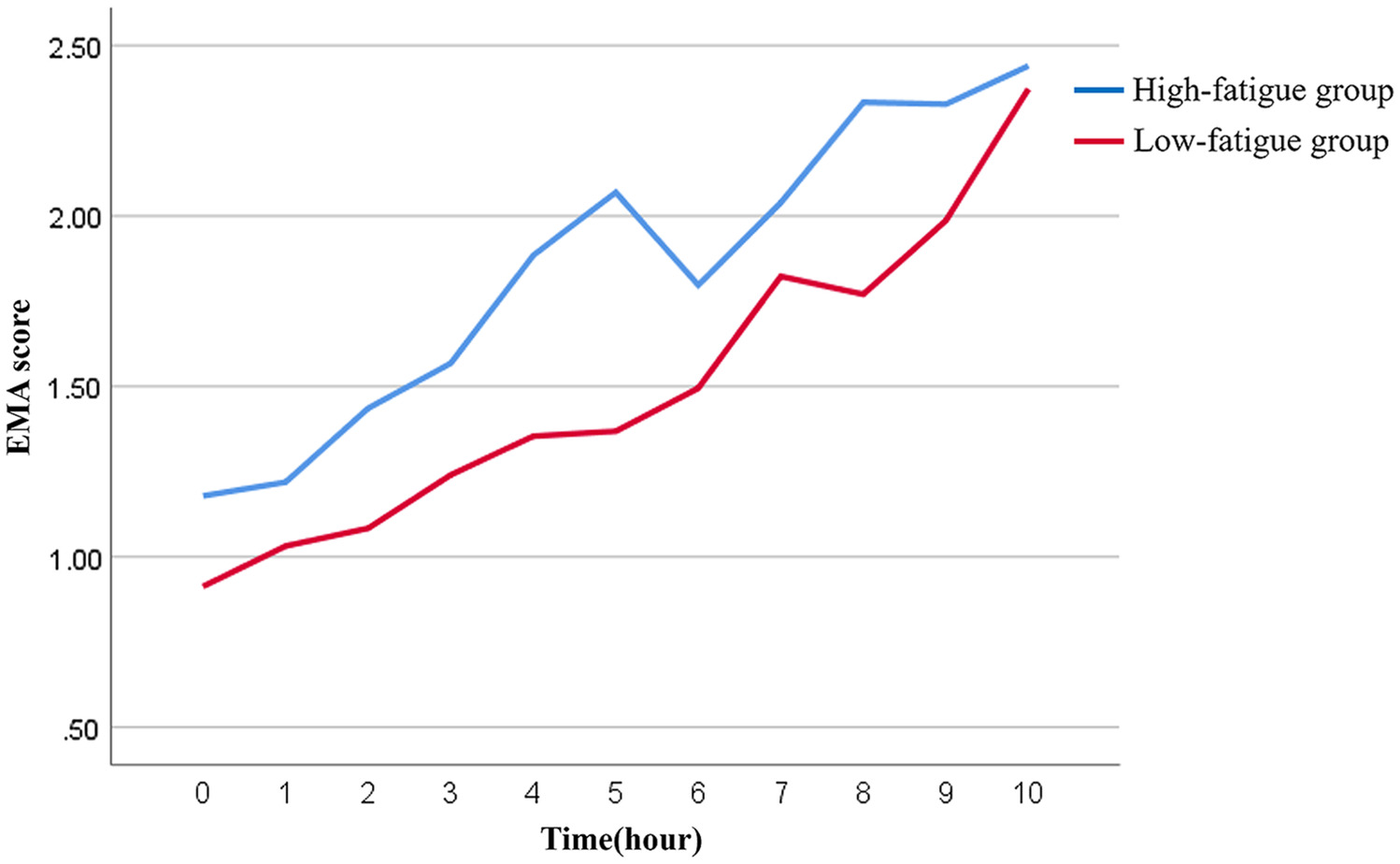

The fatigue evaluation was examined using three factors. Objective fatigue was measured using HR and activity, and subjective fatigue was measured using EMA scores. Objective fatigue factors (HR and activity) were affected by characteristics of the construction field, such as the early start of work, heavy workload, and poor work conditions. Between 10 a.m. to 12 p.m. and 3 p.m. to 5 p.m., construction workers should be checked for work-related fatigue, and actions should be taken. The participants’ subjective fatigue increased as time progressed through the day, and most workers became conscious of physical fatigue at the end of the workday. However, objective and subjective fatigue did not concur completely during the work period, as the participants were not conscious of fatigue due to factors such as work experience, long work hours, and high focus on work. These results explain why objective and subjective fatigue should be considered together. The high-fatigue group appeared to have a high level of fatigue at all working times in both subjective and objective aspects. Especially, subjective fatigue was constantly reported at a high level in the afternoon. It indicates that occupational fatigue should be managed not to cause some adverse effects on their work.

This study makes major contributions to the construction field. First, it explored changes in ongoing subjective and objective work fatigue among construction workers by considering fatigue multidimensionally with a single measure. Second, it confirmed the utility of EMA as a subjective fatigue assessment method by utilizing a real-time framework using EMA in an actual field. As the construction field has several issues, such as work devoted to human resources, industrial accidents, and efficient safety management, the proposed framework can be used as a foundation for constructing safety management with priority given to construction workers. Therefore, this study is expected to provide a foundation for the construction field to further analyze workers’ fatigue and improve the working environment.

While this study offers considerable advantages over previous studies, the findings of this study should be interpreted while considering the following limitations. The first relates to the limitation of diversity in data collection. We only collected physical data (HR, accelerometer, gyroscope), which could be collected using a smartwatch sensor. Fatigue-related physical data should be collected diversely by considering various sensors and measurement techniques. In particular, employing a PPG sensor to assess HR variability, presents its respective challenges. Therefore, using the raw HR based on bpm was explored for fatigue evaluation. Environmental factors, such as temperature, humidity, weather, and discomfort index, should also be collected, as they can affect fatigue. These factors are essential for the construction field with a lot of outdoor work, as the consideration of environmental factors can have important implications on productivity. The limitation of data type creates difficulty in evaluating work-related fatigue. The second limitation is the use of sensor data. We only the accelerometer data for estimating activity value. GYRO was excluded because GYRO is better at inferring work type rather than physical fatigue. Therefore, fatigue should be discussed in-depth while considering work type, work characteristics, and action patterns. Third, this study was conducted using data from three days. As such, we did not attempt to identify the accumulation of fatigue or quality of sleep. Although we used physical data (HR and activity) for evaluating fatigue, these data may be limited for understanding personal health.

Future research is necessary to enhance and address a broader variety of factors. The results of this study revealed several areas for useful further investigation. First, the effects of workers’ personal characteristics, such as work type, work experience, age, and health, on fatigue should be considered. As work patterns can be inferred using GYRO data, which was not used in this study, it should be considered in future studies. Second, long-term observations of fatigue should be conducted. This study conducted a field experiment over only three days to measure and evaluate fatigue at actual construction sites. In future studies, an enhanced measure and evaluation should be performed on long-term or accumulated fatigue. Accordingly, future studies with diverse datasets and various measurement sensors should evaluate subjective and objective fatigue to provide more accurate and reliable conclusions.