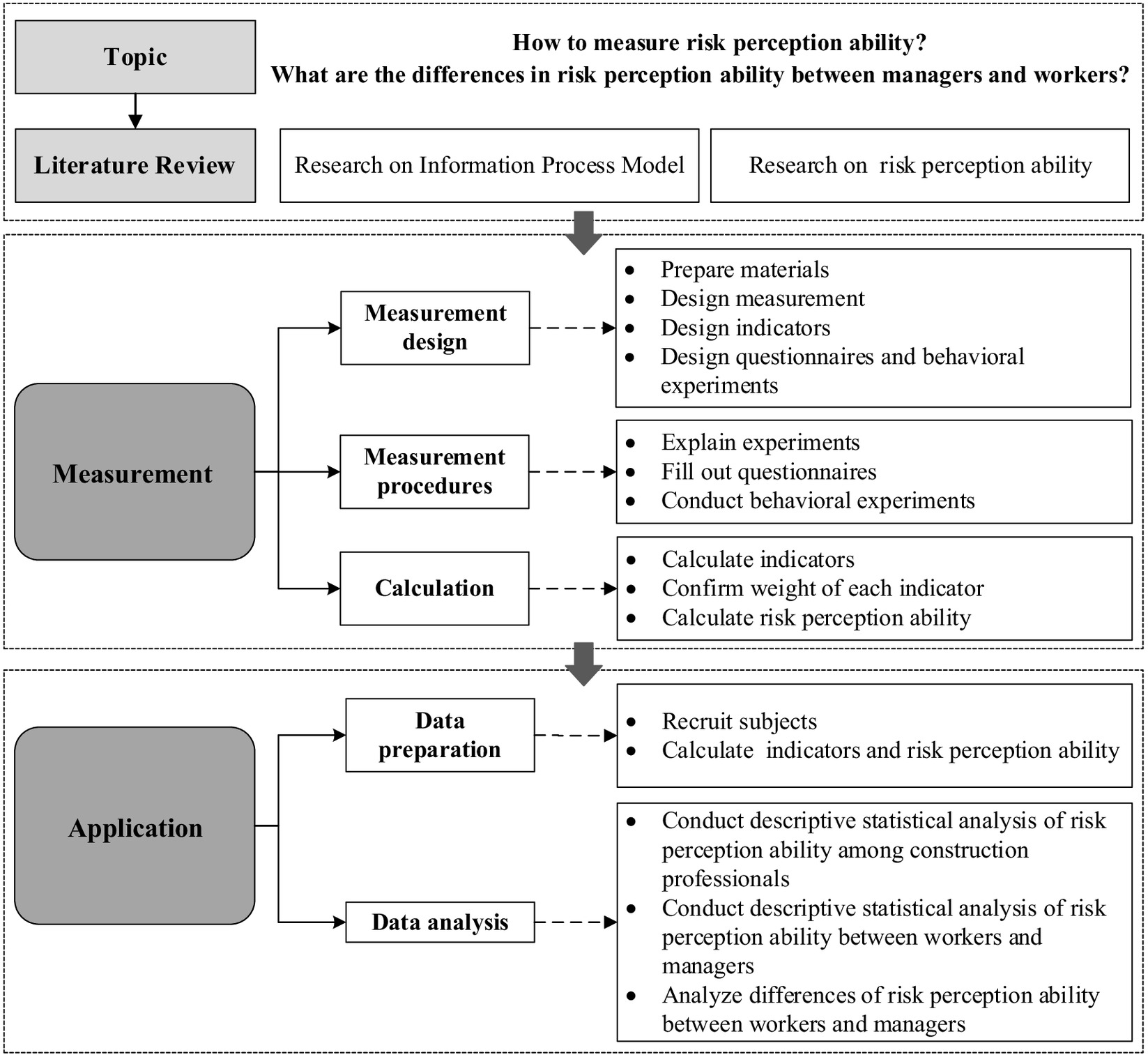

Introduction

Most accidents occur due to individuals’ unsafe behaviors (

Seo 2005). The human factors analysis and classification system (HFACS) offered a systematic review of individual factors causing accidents, in which perceptual errors are recognized as crucial errors in unsafe acts (

Shappell and Wiegmann 2000). Previous research has also indicated that failure to adequately evaluate risk may be a fundamental factor contributing to unsafe behaviors (

Na et al. 2019). In daily life, individuals can vary significantly in their capacity to identify hazards and evaluate risks. These differences can influence their behaviors, and incorrect behaviors may potentially result in accidents. So, research on risk perception is crucial for ensuring safe construction practices.

The concept of risk perception ability (RPA) and its impact on safety have gained significant attention through increased research—particularly concerning drivers. Using dynamic traffic scenarios, Spicer (

1964) was the first to measure drivers’RPAthrough situational tests (

Farrand and Mckenna 2001). Further, RPA was first defined as the ability to identify potential risks in traffic scenes (

Crick and McKenna 1992). Using a questionnaire survey (

Vanlaar and Yannis 2006), behavior experiments (

Rosenbloom et al. 2015), simulation technology (

Casutt et al. 2014), and eye movement technology (

Pradhan et al. 2003), subsequent studies explored factors that affect drivers’ RPA and figured out how to measure RPA. Through questionnaires and behavior experiments, Salmon et al. (

2013) compared drivers’ RPA and prejudgment ability with hazard identification tasks via videos featuring actual working processes. However, there has been a lack of research exploring the RPA in fields such as public safety, mine safety, and construction safety. Li (

2005) assessed students’ RPA and explored how individual differences impact their RPA. Perlman et al. (

2014) tested superintendents’ ability to identify risks, perceive risks, and assess risks with behavioral experiments.

Various methods have resulted in two types of measurement indicators: behavioral indicators and physiological indicators. McKenna and his colleagues (

McKenna and Crick 1992) have used reaction time data as an indicator of drivers’ RPA. Similarly, Yang has used hazard identification time and reaction time to measure driver’s RPA (

Yang et al. 2014). By utilizing questionnaires (

Wang 2018) and dangerous scenario videos (

Borowsky et al. 2010;

Salmon et al. 2013), participants were required to evaluate or describe the risk of hazards within a scenario, and the results were used to assess individuals’ RPA. Prior research by Chen et al. (

2016b) has attempted to measure RPA in construction workers by utilizing indicators such as hit rates and false alarm rates. Meanwhile, some scholars have combined eye movement and neuroscience techniques to explore individuals’ risk perception abilities. The indicators included driving speed, risk identification rate, gaze time, gaze frequency, and brainwave indicators (

Liang and Lin 2018;

Qiao et al. 2022;

Tang et al. 2013). Based on a picture-based risk perception experiment of road hazards, Liang and Lin (

2018) recorded 42 drivers’ electroencephalography (EEG), electrodermal activity (EDA), and behavioral responses to hazards. The results showed that physiological features were significantly different between risky and safe drivers, indicating that physiological indicators can also be applied to study individuals’ risk perception.

Thus, there are three main characteristics in current research on RPA. First, the research on RPA mainly focused on the field of traffic safety, with a majority focusing on drivers’ risk perception abilities. The construction field still lacked related studies. Second, the main research methods used are questionnaire surveys and behavioral experiments, with some studies utilizing technologies such as eye tracking and event-related potential (ERP). The two main types of measurement indicators were behavioral and physiological indicators. Finally, most related studies concentrate more on hazard identification, which ignores the evaluation of risks, and the related indicators were not comprehensive or systematic.

The construction industry has long been viewed as highly risky due to its complex work environment, overlapping tasks, and long life cycles. According to statistics from 2004 to 2021, national construction had 12,801 accidents and 15,193 deaths. As such, many experts have explored ways to effectively reduce accident rates. Deviations in individual risk perception induce unsafe behaviors (

Liang 2022) and wrong decision making (

Xiao 2014). Construction workers’ risk perception also plays an important role in improving emergency response and committing to safety regulations (

Siegrist and Arvai 2020;

Wang et al. 2016). Risk perception was mainly defined as a subjective feeling toward risks, without right or wrong, just low or high. Different from risk perception, RPA was a kind of capacity (

Crick and McKenna 1992). We defined RPA as an ability to quickly and correctly identify hazards in the target scenario, to objectively analyze the probability and the damage of potential accidents caused by hazards, and to evaluate the risk level of the hazards relatively accurately. As said before, the construction field lacked studies relating to RPA. So, we reviewed the literature on risk perception in construction. As a stage of risk perception, the failure to identify hazards would result in unsafe behavior (

Tixier et al. 2014). Hazard identification is one of the fundamental units of risk management. Currently, scholars have conducted extensive research on the hazard identification stage in construction. Dzeng et al. (

2016) compared the hazard search patterns of experienced and novice workers by creating a construction site model. Chen et al. (

2016a) utilized a helmet system integrated with electroencephalography to identify individuals who demonstrated weaker abilities in hazard identification. By experimental research, Atefeh et al. (

2018) discovered that the time to the peak value of hemoglobin concentration varied with the degree of hazard and the source of energy. Previous studies concentrated more on the hazard identification stage and ignored the importance of the risk evaluation stage. An accurate evaluation of risks is also crucial in shaping safety behavior among construction workers. Underestimating risks can foster a sense of recklessness, which in turn can induce unsafe behaviors. Conversely, overestimating risks can induce feelings of fear and anxiety among workers, ultimately resulting in errors and mistakes in their work. Hence, we studied RPA from two stages: hazard identification and risk evaluation.

Accordingly, this study primarily focused on RPA from two perspectives: hazard identification and risk evaluation. We aimed to design a measurement for RPA. Based on existing indicators measuring RPA, we designed an indicator system and proposed a formula to calculate RPA. Through questionnaires and behavioral experiments, we measured construction professionals’ RPA, and we further studied whether ability discrepancy between managers and workers exists. This study addresses the research gap in RPA within the construction industry. In addition to hazard identification, this study refocuses on the risk evaluation stage of risk perception, and it holds practical significance for construction safety work.

Calculation of RPA

Weight Calculation

The weighing values for the indicators were computed. Methods confirming weight had two kinds: subjective and objective (

Fan et al. 1998). The subjective weighting method mainly depended on policymakers’ subjective preference and direct experience, such as the expert investigation method (

Li et al. 2014), the Delphi method (

Cheshmidari et al. 2017), the analytic hierarchy process (AHP) (

Joukar et al. 2016). The objective weighting method created a decision matrix and enlisted mathematical models to compute weighing values, such as principal component analysis (PCA), multiobjective optimization (MOP), and criteria importance through intercriteria correlation (CRITIC). In this paper, a synthesized method is proposed according to the advantages and disadvantages of subjective and objective ways of giving weight. Based on game theory (

Chen 2018), we used Nash equilibrium as the goal coordination method and combined the AHP and CRITIC to lessen errors.

As an objective method to compute weighing values, CRITIC measures a criterion by considering both the importance itself and the conflict caused by intercriteria (

Li et al. 2012). The calculation process is as follows.

1.

Data preprocessing: eliminate dimensionality effect, each indicator was normalized.

2.

Evaluate indicators’ volatility and coefficient of friction.

We used a computer algorithm to implement its computation, and the results are as follows:

The AHP is a subjective weighting method that prioritizes the relative importance of each factor via pairwise comparisons among the factors by relevant experts using a nine-point scale (

Zhu et al. 2015). The specific steps and calculation process are as follows:

1.

Structure the judgment matrix.

2.

Examine the consistency of the comparison matrix.

3.

Compute the values of weight.

The 32 nine-point scales were distributed to related professors, safety experts, and safety managers, and 30 were valid. The calculated process was conducted by a computer algorithm, and the results are as follows:

Based on the Nash equilibrium of game theory, Su et al. (

2014) combined the subjective weighting method and objective weighting method to obtain more scientific results. The basic idea was to seek balance among weights obtained from different methods, aiming to minimize the deviation between basic weights and final weights. The decision model is shown as follows:

The condition of optimal first-order derivative is

where

= coefficient which meets weight vector

According to the results of the subjective weighting method and objective weighting method,

= [0.1679, 0.1614, 0.2148, 0.1446, 0.1513, 0.16],

= [0.1689, 0.1485, 0.1476, 0.1946, 0.1871, 0.1533], the weight-vectors

were put into the formula, and the integrative model was shown

After calculation, , and .

Consequently, it is clear that the final weight vector was: . The weights of HID, HIA, ARE, DD, DP, and DRE separately are 0.168, 0.168, 0.17, 0.187, 0.157, and 0.15.

As shown, for the hazard identification stage, HID, and HIA had the same weights, yielding that both indicators should be taken seriously. For the risk evaluation stage, the deviation degree of the expected damage had the largest weight, showing that the deviation degree of the expected damage may be more important in risk evaluation.

Calculation of RPA

Based on the content above, weight of the indicators were determined. The formula of RPA was obtained as follows:

Because the range of each indicator varies. Hence, all indicators were classified into five degrees, and every degree was assigned a value. Finally, the formula can be used to calculate RPA by the assigned value of each indicator. Specific assignment criteria can be found in the following calculation examples.

Discussion

Design of Indicators

Previous studies explored risk perception mainly from two stages: perceptual and cognitive processes. While exploring differences in risk perception between new drivers and experienced drivers, Tang et al. (

2014) divided the processing of risk perception into perceptual and cognitive processes. Applying neuroscience, Ma et al. (

2010) explored the identification mechanism of safety signs and established a two-stage model of risk perception, the early automatic attention stage, and the evaluation stage. However, in the field of construction, scholars have primarily focused on hazard identification, with some scholars measuring risk perception abilities solely from this perspective (

Crick and McKenna 1992). The critical component of risk evaluation in risk perception should not be overlooked. Extensive research has been conducted to study risk evaluation in risk perception (

Li 2005;

Perlman et al. 2014), but not in RPA. Building upon this, our study encompasses both hazard identification and risk evaluation in measuring risk perception abilities. We have developed six indicators to measure individuals’ risk perception abilities from two parts: hazard identification ability and risk evaluation ability. To assess the abilities, we have used both questionnaires and behavioral experiments, measuring 327 construction professionals’ risk perception abilities. In our study, a person with higher RPA is characterized as identifying hazards correctly, judging the probability and damage of potential accidents, and the risk level of hazards objectively and rightly. In contrast, those with lower RPA tend to identify hazards wrongly or partially and may overestimate or underestimate the probability, damage, and risk level, leading to a larger deviation in risk perception.

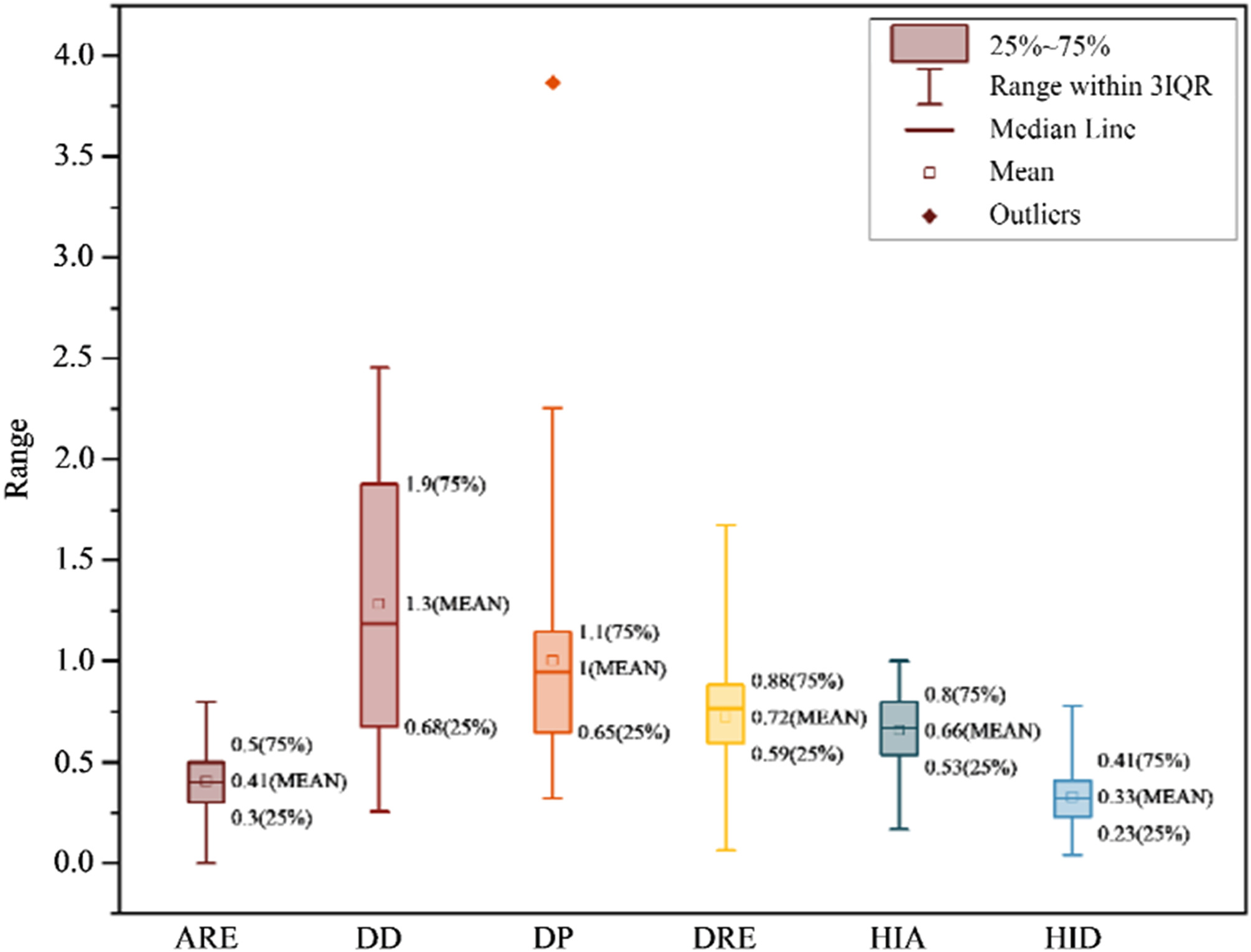

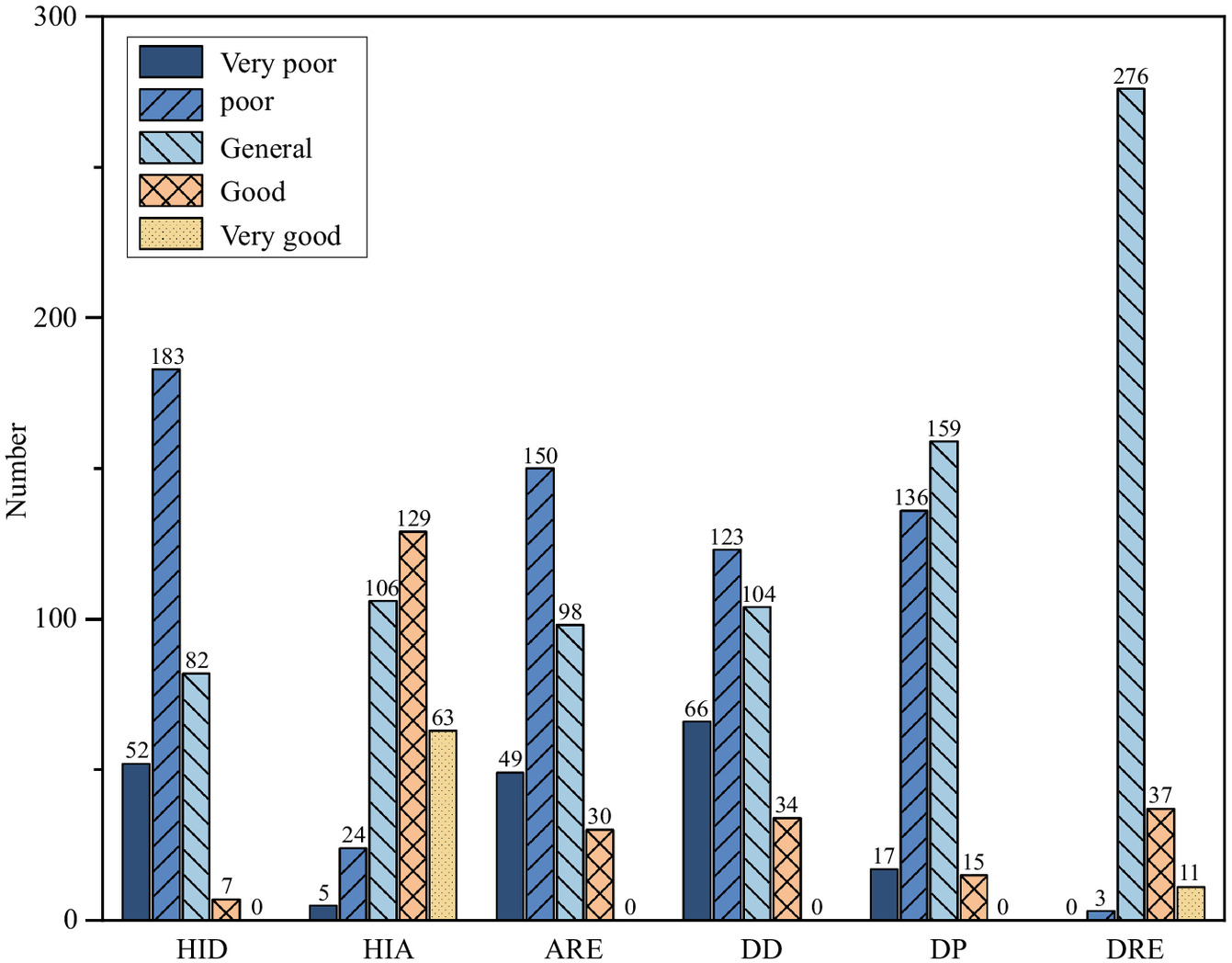

The distributions of indicators and RPA we measured are shown in Table

11. Regarding indicators of the hazard identification stage, 57% of participants’ HID was poor, with 25% being categorized as general; 40% of participants had good HIA; and 32% of them had general hazard identification accuracy. So combined, construction professionals have difficulty in identifying all hazards depicted in pictures; however, they have high accuracy in their identified hazards, reflecting they rarely recognize normal scenes as hazards but could not identify hazards comprehensively.

In terms of indicators in the risk evaluation stage, 46% of participants had poor ARE (S-ARE), while 30% had general ARE; 38% of participants’ deviation degree of the expected damage (S-DD) was poor, and 32% of that were general; 49% participants had a poor rate of deviation DP (S-DP), and 49% participants had general rate; and 85% participants’ deviation DRE (C-DRE) was general. Except for the deviation DRE rate, other indicators were mainly in general or poor level. Construction professionals struggle to evaluate the risk level accurately, the deviation exists when they evaluate risk level. Subsequently, the deviation of expected damage and probability was large, suggesting that construction professionals fail to correctly comprehend the expected harm and probability of hazards.

The results presented show that the measurement indicators for construction professionals can vary. Focused on differences in risk perception, previous studies indicated that managers’ risk perception was significantly different from that of the general public (

Li et al. 2018), different groups judged risks differently in the construction industry (

Zhao et al. 2016), different genders also had different risk perception (

Alsharawy et al. 2021), and risk perception varies from ages (

Rosi et al. 2021). From data analysis in our study, the HIA (

), HID (

), DD (

), and DP (

) of workers were significantly different from managers. The results revealed that the discrepancy in RPA between workers and managers existed in our study. To some extent, the measurement results of indicators can indicate the rationality of indicator design.

The Calculation of RPA

In the calculation process, the determination of indicator weights considers not only expert recommendations but also objective data, thereby enhancing the persuasiveness of the obtained results in measuring RPA. After that, Eq. (2) was obtained.

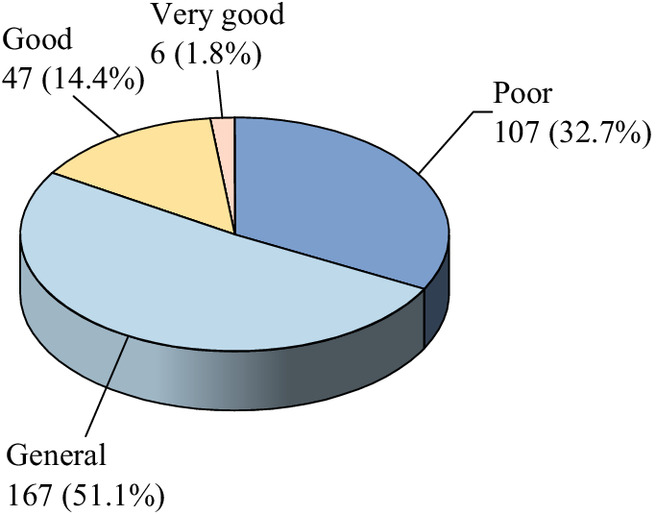

The indicators, such as HID, HIA, and ARE, showed the right rate and identification number of participants. So, they are positively correlated with RPA. Indicators, such as deviation degree of the DD, DP, and DRE, which indicated the deviation of risk evaluation, were negatively correlated with RPA. As to the results of RPA, for 327 construction professionals, 32.72% of them had a poor risk perception ability, 50.76% of them had a general risk perception ability, and 15.60% of them had a superior risk perception ability, revealing the differences in risk perception abilities among construction professionals.

Managers’ RPA was larger than workers’ (

), meaning managers’ risk perception ability was superior to workers. The results proved the risk perception discrepancy between workers and managers exists, which was the same as Song and Zhang (

2022).

In conclusion, the ways of calculating risk perception we proposed can used to measure construction professionals’ RPA. This calculation method effectively demonstrated differences in abilities among construction professionals and between workers and managers. It is scientifically valid to a certain extent.

Implication

The method proposed in this article expands upon previous research on risk perception abilities, specifically focusing on risk perception abilities in construction safety. Our measurement offered a comprehensive and systematic examination of individuals’ risk perception abilities by considering two parts of RPA: hazard identification ability, and risk evaluation ability which was neglected by previous study.

From a practical perspective, the proposed method for measuring risk perception abilities is straightforward and easily implementable. It has broad applicability not limited to the field of construction safety but extends to other industries as well. This method effectively evaluates workers’ ability to identify hazards and evaluate risks, enabling management to assess the effectiveness of safety training. Moreover, by utilizing various types of hazard pictures, workers can undergo testing to identify any misconceptions in hazard identification and pinpoint shortcomings in their understanding of risks. This, in turn, facilitates the development of tailored and targeted safety training programs, which are aimed at enhancing workers’ risk perception abilities and expanding their knowledge of risks.

To achieve this, additional training and resources should be provided to expand their knowledge and understanding of hazards. Safety training should be conducted to increase personnel’s sensitivity to hazards. By watching videos or pictures, hazards ought to be introduced thoroughly to increase construction professionals’ familiarity with hazards. Moreover, construction professionals should strengthen their ability to recognize hazards’ risk levels, expected damage, and probability. Combined with accident cases, a detailed and comprehensive explanation of these factors can help them to understand hazards more deeply. An accurate and objective judgment not only helps workers avoid unsafe behaviors but also assists managers in making the proper decision for safety management.

Limitations and Future Research

We formulated a novel evaluation method to measure construction practitioners’ RPA. The results revealed that managers’ risk perception abilities were superior to workers’. Nevertheless, there were certain shortcomings in the research, which should be addressed in future studies.

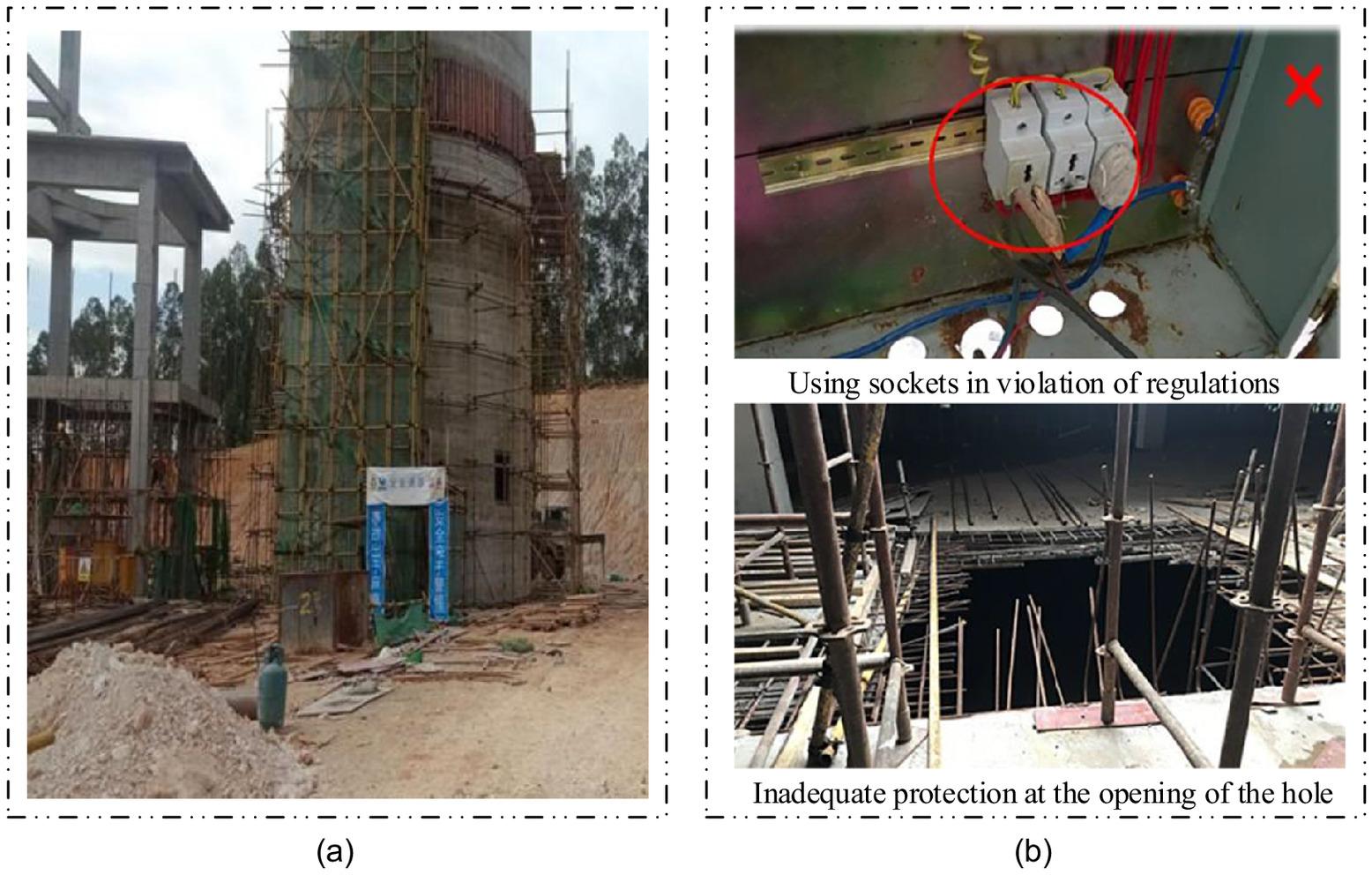

Primarily, the RPA covers two parts: a questionnaire survey and a behavioral experiment. The samples selected for this research were representative of front-line construction practitioners, whereas the hazard stimulus materials included various risks associated with construction sites. However, some studies showed that flat stimuli can potentially distort information, consequently biasing subjects’ understanding of risk information. Subsequent studies should consider the use of real-scene videos or VR scene simulations as hazardous stimulus materials. Second, this paper mainly measures subjects’ RPA through subjective judgments, and no objective physiological data were considered or analyzed. Some scholars combined neuroscience techniques such as electroencephalography (EEG) and functional magnetic resonance imaging (fMRI) to study the risk perception process (

Ma et al. 2010;

Qin and Han 2009). Scholars such as Zhang et al. (

2021) also proposed the necessity of using neuroscience techniques to study risk perception. In future studies, research methods should be broadened, such as using event-related potentials to study brain activity during hazard identification and risk evaluation. Finally, to effectively apply the measurement of RPA, we should consider how to conduct the measurement through automatic processes, such as developing a software program.