Introduction

The application of performance-based design approaches in structural fire engineering is gaining increasing momentum. These approaches are usually applied in deterministic assessments (

Bernardi et al. 2020;

Fischer et al. 2019;

Gernay and Elhami Khorasani 2020;

Martinez and Jeffers 2021), where the effects of randomness in input parameters are not explicitly quantified. Deterministic analyses do not consider the full set of likely outcomes. Yet structural fire analyses involve a large number of uncertain parameters. These include the permanent and live loads, fire load density, and temperature-dependent material properties, among others. Therefore, probabilistic analyses constitute a more reliable approach to support fire safety designs of new structures. Moreover, as suggested by Garcia-Castillo et al. (

2021), probabilistic analyses can also help to preserve existing structures (e.g., historic ones) designed when modern codes did not exist, thereby contributing to more sustainable construction.

Probabilistic fire analyses require stochastic models able to capture the inherent variability of the input parameters involved in the corresponding thermal and mechanical simulations. For this reason, probabilistic models for specific parameters within structural fire engineering have already been developed. Some examples are the probabilistic model proposed by Jovanović et al. (

2020) for permanent and live loads and that suggested by Khorasani et al. (

2014) for the fire load density in office buildings. The temperature-dependent mechanical properties of the materials are also a determining parameter when assessing the fire performance of structures. Thus, probabilistic models of the retained strengths of steel and concrete at elevated temperatures have been recently proposed (

Qureshi et al. 2020). However, to the authors’ knowledge, no such models exist for timber, despite the increasing popularity in its use as a building material and its associated environmental benefits (

Barber 2018;

Hildebrandt et al. 2017;

Hill 2019). Standards and research efforts have focused solely on the probabilistic characterization of timber’s strength at room temperature (

JCSS PMC 2006;

Sørensen and Hoffmeyer 2001;

Volynsky 2006).

Currently, fire design of timber structures can be addressed through either prescriptive or performance-based approaches. Within the former, the reduced cross-section method of EN 1995-1-2 (

CEN 2004c) and the 2018

National Design Specification (NDS) for Wood Construction (

AWC 2018) proposed to assume an effective cross section for structural calculations in fire situation. The effective cross section is obtained by reducing the original cross section by the charring depth and an additional thickness that accounts for the decrease in strength and stiffness of the thermally affected timber behind the char front. Thus, the aforementioned codes provide charring rate values and expressions to determine these parameters.

Alternatively, EN 1995-1-2 (

CEN 2004c) suggests temperature-dependent thermal and mechanical properties of timber for use in numerical simulations when assuming performance-based approaches. Specifically, for the mechanical properties, EN 1995-1-2 (

CEN 2004c) established bilinear relationships that define the reduction in timber strength and stiffness with increasing temperature. These deterministic relationships were back-calculated by König and Walleij (

2000) based on the structural response of timber frame assemblies submitted to the standard ISO 834-1 (

ISO 1999) fire exposure in a limited number of experimental tests. Several authors have suggested similar deterministic models (

Thomas 1996;

Van Zeeland et al. 2005). More recently, Naser (

2019) used artificial intelligence to develop temperature-dependent constitutive material models for timber based on experimental data and deterministic models collected from the literature. As a result, simple expressions to predict the thermal and mechanical properties of timber as a function of temperature were derived.

Multiple published studies have provided experimental data on the reduction of timber strength at high temperatures. As indicated by Kuronen et al. (

2021), Manríquez Figueroa and Dias De Moraes (

2016), Wiesner et al. (

2021), and Zaben et al. (

2020), this topic is of major concern, especially with the advent of mass timber construction. Recently, several sources have collated the experimental data reported in the literature (

LaMalva and Hopkin 2021;

Naser 2019), revealing a large variability among these. This variability could be partly explained by the differences in heating and loading conditions assumed in the experimental tests, among other factors related to the features of the specimens.

In fact, as concluded in a literature review conducted by Gerhards (

1982) and in various subsequent works (

Manríquez Figueroa et al. 2015;

Östman 1985;

Wiesner et al. 2021), moisture content has a strong influence on timber strength at high temperatures. However, the influence that other factors and their possible interactions might have on the variability of the experimental data remains uncertain. These factors include the wood species, the density and size of the specimen, and the presence or absence of knots and other wood defects, among others. Therefore, notwithstanding the relevance of this type of studies to better understand the effects of elevated temperatures on timber strength reduction, their results might be highly influenced by numerous factors, and their findings may not apply to all cases. In addition, the lack of normalization of the experimental tests complicates discernment of the reasons for the observed differences.

The deterministic nature of the current temperature-dependent timber strength-reduction models hinders the consideration of the observed variability in probabilistic fire risk analyses. Furthermore, the evident disparity between the commonly adopted models of EN 1995-1-2 (

CEN 2004c) and the experimental data from the literature calls into question the reliability of the fire safety designs of timber structures. Thus, the development of robust models for timber strength as a function of temperature is pressing.

Within this context, this paper proposes probabilistic models that capture the uncertainty of the compressive and tensile strengths of timber at high temperatures. These models are based on experimental data gathered from an extensive literature review. The importance of the contribution lies in the fact that these models can be applied to the probabilistic assessment of the structural performance of timber structures against fire to evaluate their reliability. In addition, the suggested models can be easily implemented in a numerical code, facilitating their use in analytical and computational approaches. Therefore, this work aims to promote the design of reliable and efficient timber structures with respect to fire safety.

Finally, by reducing the inherent uncertainty, this study fosters the use of timber as a building material in new construction, as well as the rehabilitation and preservation of timber elements in historic buildings. Both involve important environmental benefits. Wood requires less energy in its manufacture and has a lower environmental impact and fewer toxic emissions than other contemporary building materials (

Sathre and Gustavsson 2009;

Woodard and Milner 2016), making it more sustainable. Rehabilitation of historic structures, on the other hand, in addition to allowing the conservation of built heritage, generates less environmental impact, waste, and ecological footprint than new construction (

Alba-Rodríguez et al. 2017) because it takes advantage of existing resources.

Materials and Methods

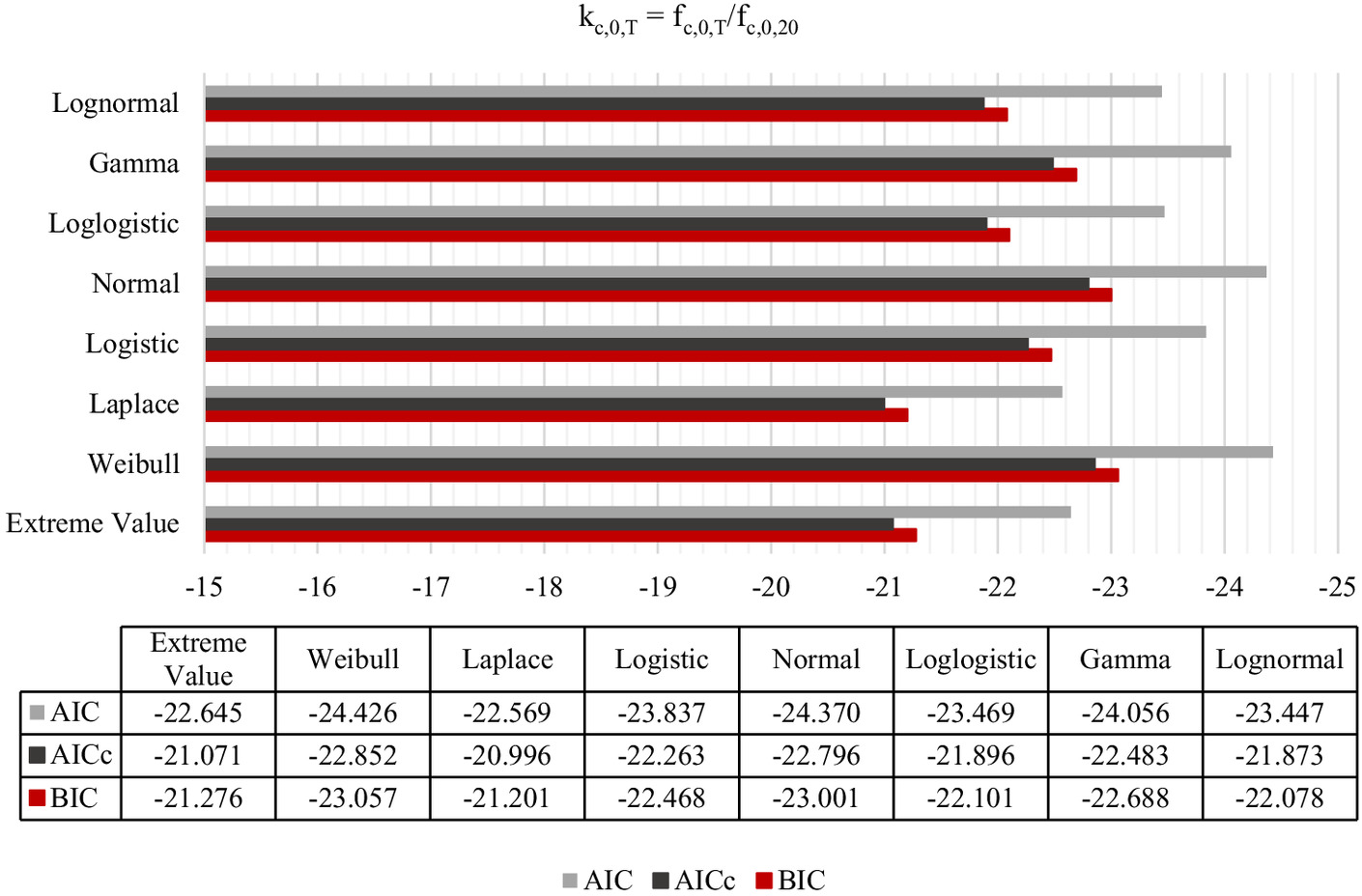

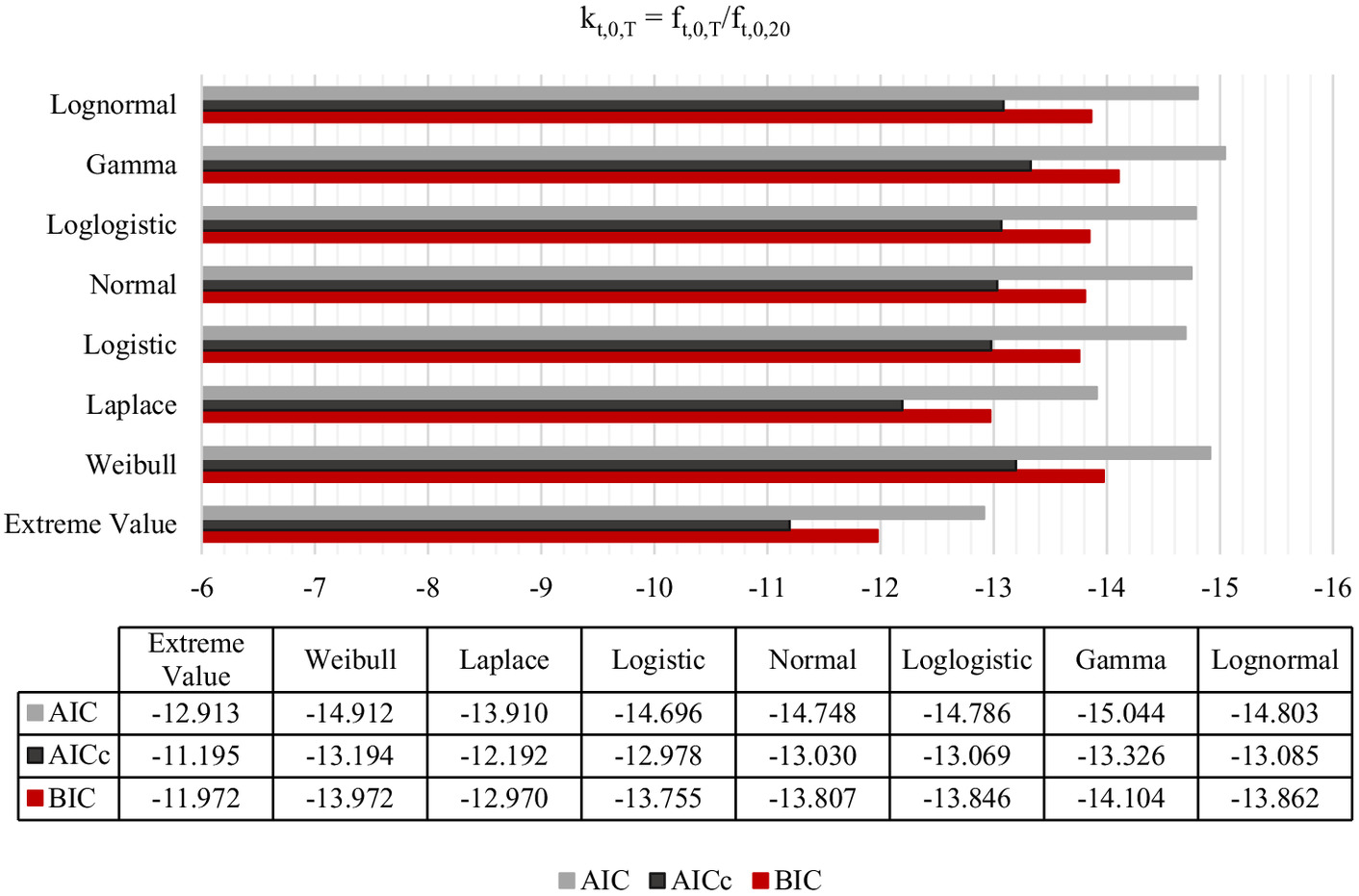

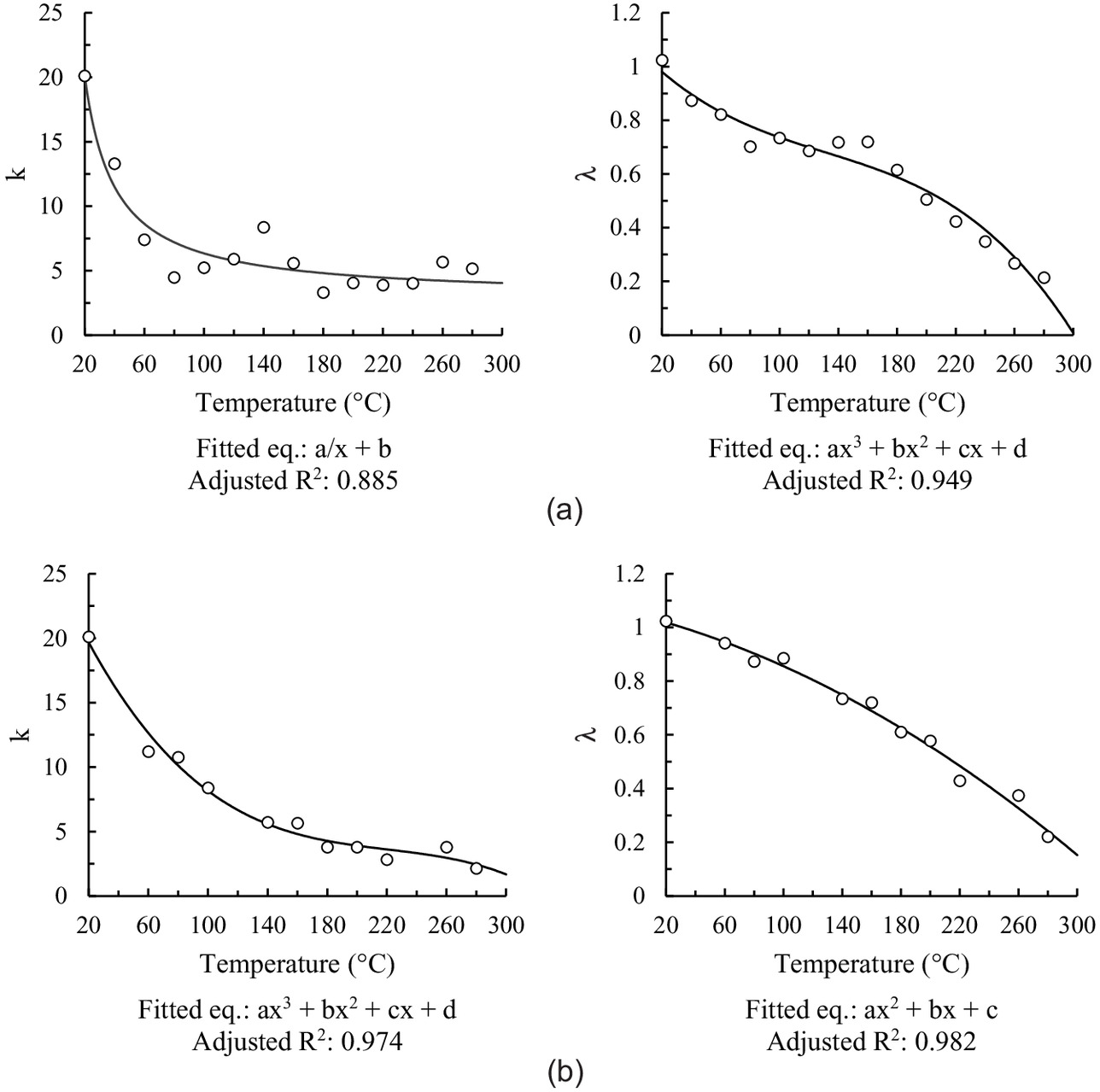

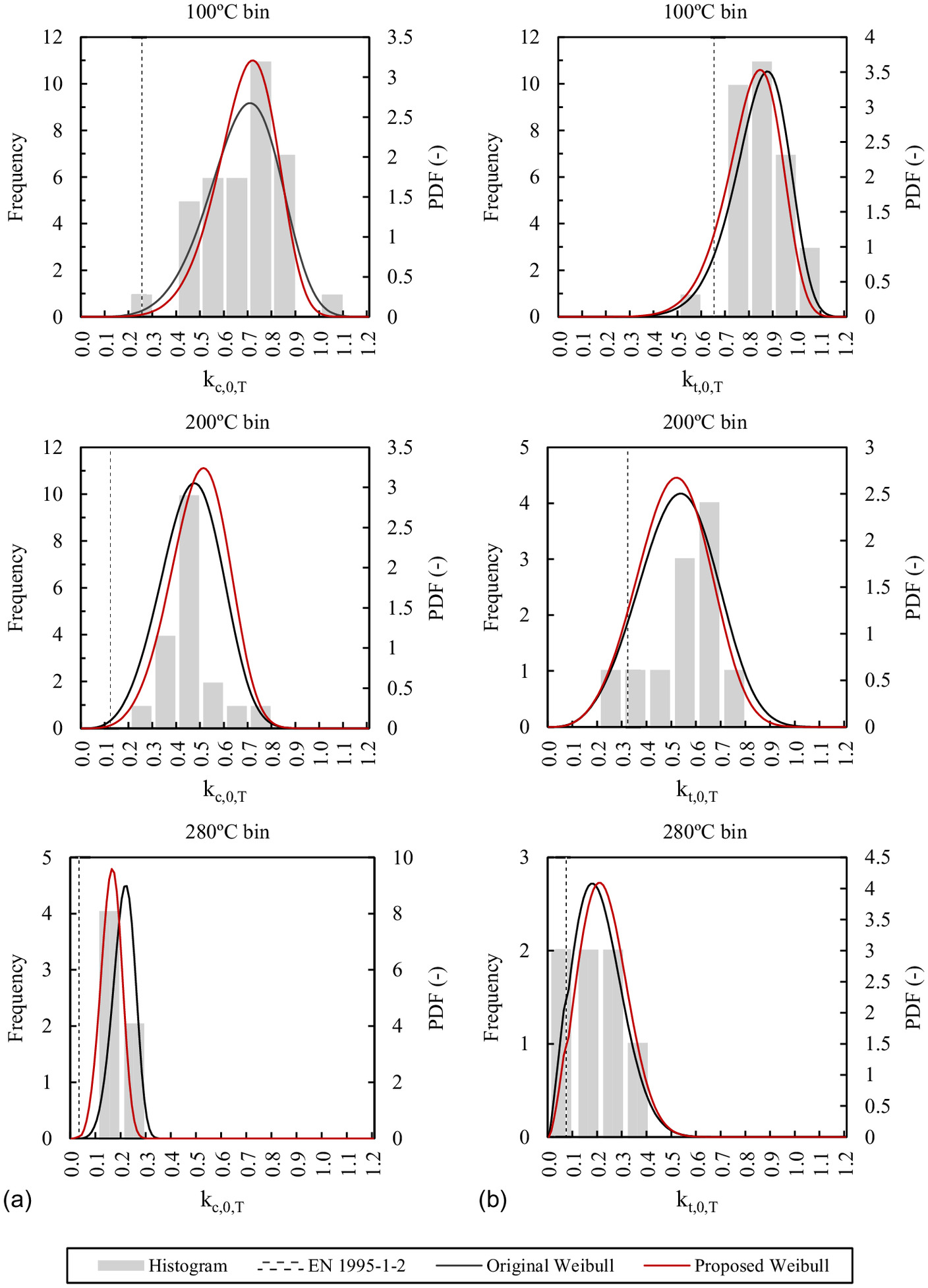

The objective of this paper is to propose probabilistic models for the temperature-dependent compressive and tensile strength–reduction factors of timber that capture the variability shown in the data. The strength-reduction factor () represents the loss of strength of a structural material with increasing temperature and is defined as the ratio of the material strength at a given temperature to the material strength at ambient temperature.

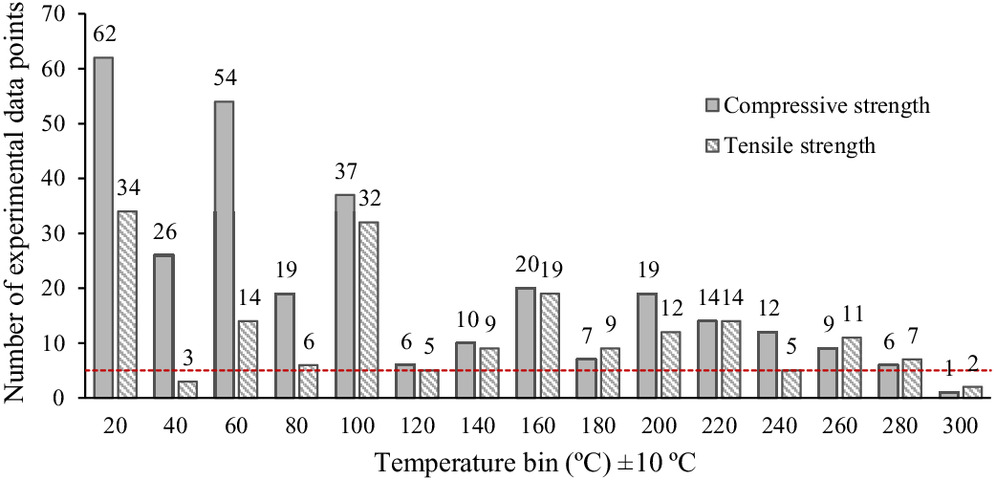

To achieve this objective, first, a comprehensive literature review was carried out to collect experimental data on timber compressive and tensile strengths at elevated temperatures. Then, the collected experimental data points were grouped into bins of 20°C temperature intervals based on a data binning technique commonly adopted in statistical analysis (

Montgomery and Runger 2019;

Zheng and Casari 2018). The temperature bins were denoted by their corresponding central value (

), as usual, starting with 20°C. Therefore, each temperature bin contains experimental data within the following temperature range: (

,

). Next, multiple probability density functions (PDFs) were fitted to each temperature bin of both compressive and tensile strengths, and three different information criteria based on the likelihood function were assumed to quantify the relative quality of goodness of fit of the candidate PDFs and select the one that provided the best fit. The following sections provide additional information on the selection, definition, and validation of the proposed probabilistic models, as well as the main features of the experimental data on temperature-dependent timber compressive and tensile strengths.

Regarding the scope of the literature review, experimental data were gathered on both timber compressive and tensile strengths parallel to grain at elevated temperatures. Due to the inherent anisotropy of the material, timber mechanical properties differ depending on the direction (i.e., longitudinal, radial, or tangential) considered (

Ross 2010). Most of the timber structural elements work in compression (e.g., columns) or in bending (e.g., beams). In both cases, the forces acting on the structural element generate compressive or compressive and tensile stresses of significant magnitude in the longitudinal direction of the element. Therefore, in this study, the longitudinal (parallel to grain) direction was assumed because it is the one that bears the highest stresses in most timber structural elements and, consequently, is the most relevant.

Thus, the temperature-dependent reduction factor for timber compressive strength parallel to grain () is the result of the compressive strength parallel to grain measured at a certain high temperature () divided by the mean value of the measured strength at ambient temperature (); the reduction factor for timber tensile strength parallel to grain () can be obtained in the same way by adopting the corresponding values of retained tensile strength parallel to grain at an elevated temperature () and the mean of the experimental measured strength at ambient temperature (). Hence, the reduction factor at ambient temperature is equal to unity.

The collected experimental data points come from high-temperature mechanical tests performed on both solid and engineered timber specimens of numerous species. The data set covers a temperature range from ambient temperature to 300°C, the latter being the commonly accepted charring temperature of wood (

CEN 2004c) beyond which timber strength and stiffness are practically negligible. Additionally, only experimental results from wood specimens with values of initial moisture content up to 20% have been included because, even in unfavorable atmospheric conditions with high relative humidity and low temperatures, these are not maintained for a sufficiently long period of time for wood to reach higher moisture contents (

Ross 2010).

In this way, experimental data from 30 different studies were included in the data set on temperature-dependent timber strengths. These studies cover the period from 1940 to present and the experimental data were available in tabular or graphical form. Those in the latter form were processed using computer-aided design (CAD) software to obtain the corresponding experimental data values. Finally, experimental data at elevated temperatures were either available in terms of strength or reduction factor. In the former case, studies that performed more than one experimental test for a given temperature generally reported the different strength values achieved. Thus, for those strength data points within the same study that were obtained under identical experimental conditions, the mean values associated with each temperature were assumed to calculate the reduction factors presented in this study.

Data on Temperature-Dependent Material Strength of Timber

Table

1 summarizes, in chronological order, the main features of the experimental tests associated with the experimental data gathered from the literature, focusing on the characteristics of the wood specimens, as well as the fire and load test conditions. It is important to highlight that some experimental data were collected from sources other than the original studies. Specifically, compressive and tensile strengths data of Khmelidze (

1986), Nyman (

1980), and Rykov (

1980) reported by Aseeva et al. (

2014), tensile strength data of Kollmann and Schulz (

1944) reported by Kollmann and Côté (

1968), and compressive strength data of Kollmann (

1951) reported by König and Walleij (

2000) were considered. In these cases, the sources consulted did not provide details of the experimental tests from which the data were derived. Hence, Table

1 does not include information on the experimental tests performed by Khmelidze (

1986), Kollmann (

1951), Kollmann and Schulz (

1944), Nyman (

1980), and Rykov (

1980).

Before discussing Table

1, a few observations are in order. Firstly, in several tensile tests, specimens with a reduced cross section in the central part were used to reach failure in that region. In these cases, the width and thickness of both the full and reduced cross sections of the specimens are given in the table, with the dimensions corresponding to the full cross section indicated in parenthesis. Secondly, for those works addressing the mechanical behavior of finger joints at high temperatures (

Frangi et al. 2012;

Klippel et al. 2014;

Nielsen and Olesen 1982;

Yue et al. 2021), as well as the assessment of adhesive performance at elevated temperatures using half-lap joints (

Zelinka et al. 2019), only experimental data from reference specimens without joints were included in the data set. Finally, the results provided by Young and Clancy (

2001) were normalized to the strength of dry specimens at ambient temperature to be consistent with the rest of the data.

Except for the experimental tests conducted by Wiesner et al. (

2021) on cross-laminated timber (CLT) specimens, all experimental data collected come from solid timber specimens. As can be observed in Table

1, wood specimens of multiple densities, moisture contents, and dimensions were assumed in the different experimental tests. Although the experimental tests conducted by Östman (

1985) considered specimens with moisture contents up to 30%, only the results from specimens with moisture contents up to 20% were included in the data set.

Concerning the heating of the specimens, with the exception of the experimental tests carried out by Wiesner et al. (

2021), heating was carried out prior to loading and, hence, under unstressed conditions. The information collected shows that, in general, specimens reached steady-state conditions in the experimental tests conducted by the different authors; however, transient conditions were also assumed by several authors (

Glos and Henrici 1990;

White 1996;

White et al. 1993;

Wiesner et al. 2021).

Overall, specimens were heated either with drying ovens or chambers or with heating plates. Exceptionally, temperature-controlled silicone oil baths (

Östman 1985) and a combustion furnace with diffuse-flame natural gas burners (

White 1996;

White et al. 1993) were used to heat the specimens. In the case of the experimental tests performed by Do and Springer (

1983), White (

1996), and White et al. (

1993), only the results from specimens exposed to heat for 60 min were considered because they are assumed to be closer to a steady-state condition than those with shorter time exposures. Finally, displacement-controlled loading (i.e., the load is applied at a constant displacement rate) was the most common mechanical test procedure for determining the timber strength.

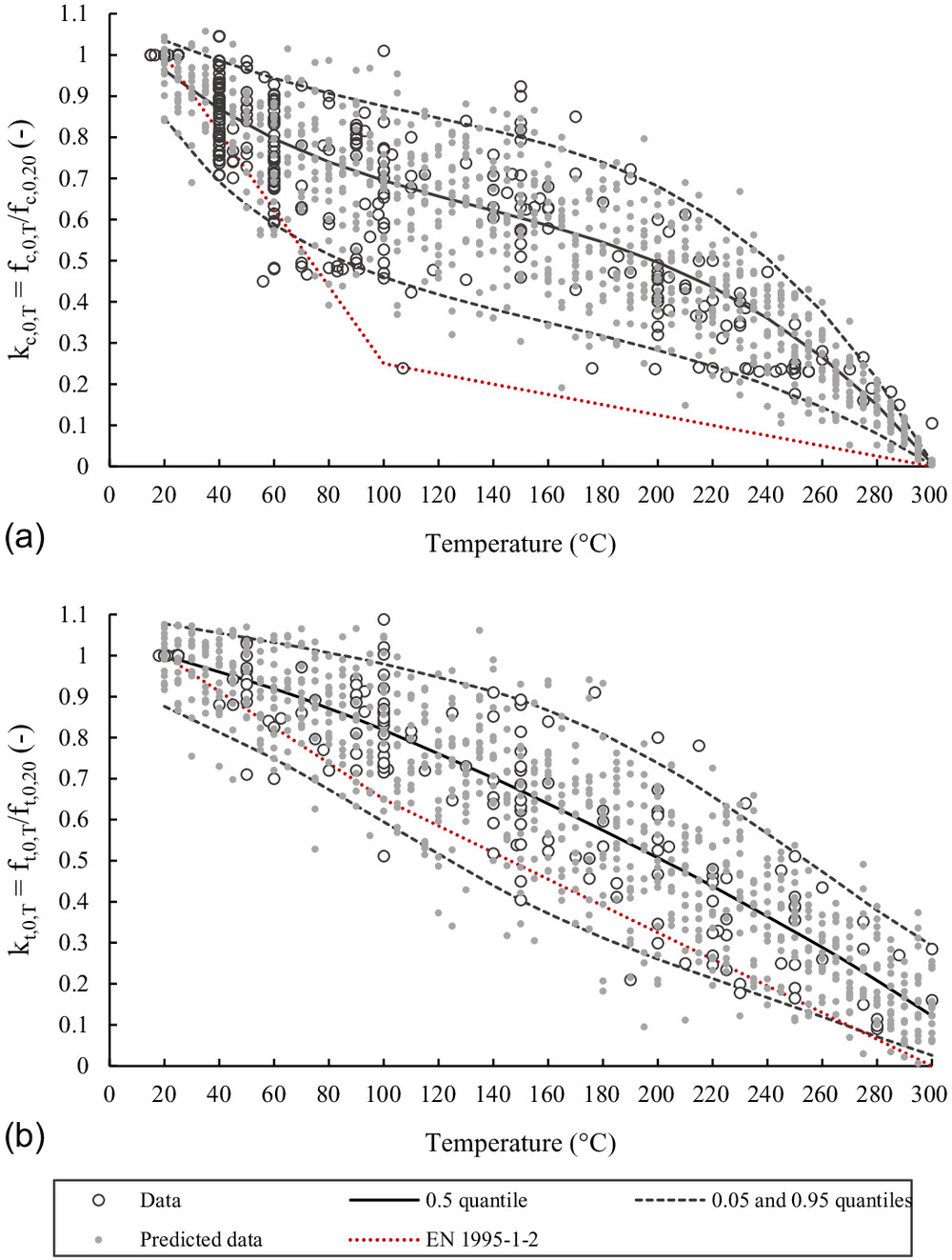

In total, 302 experimental data points for

and 182 data points for

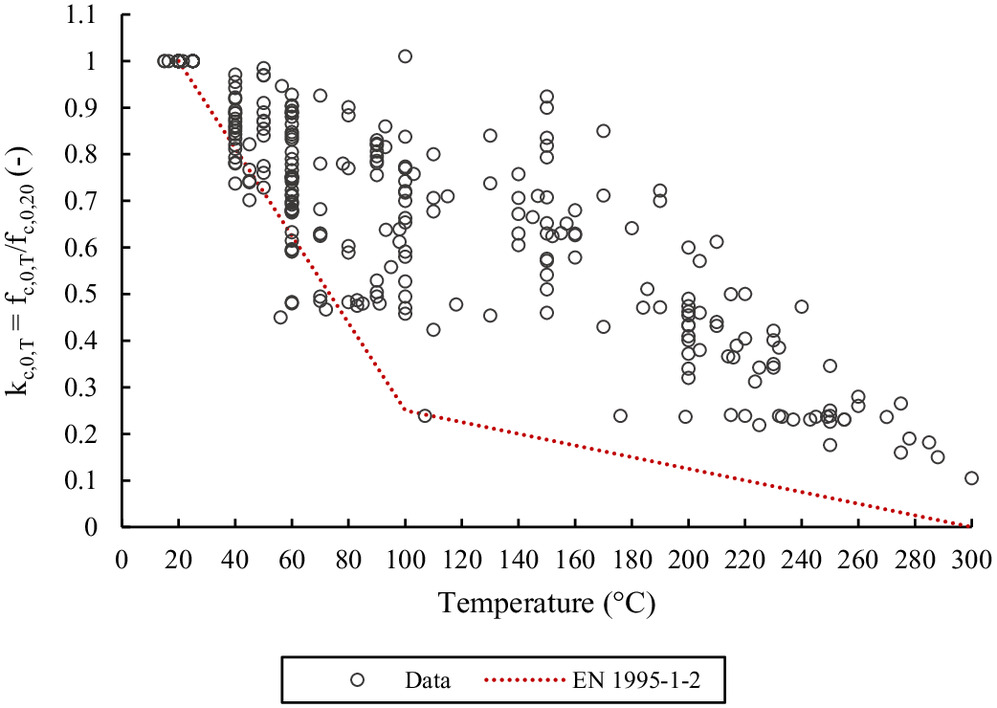

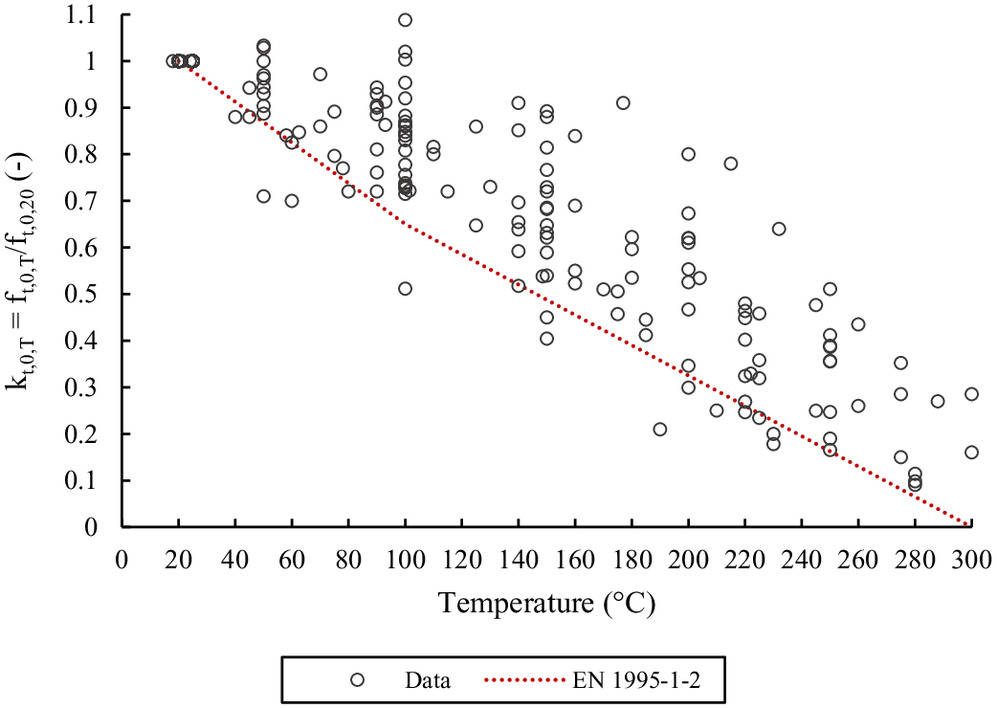

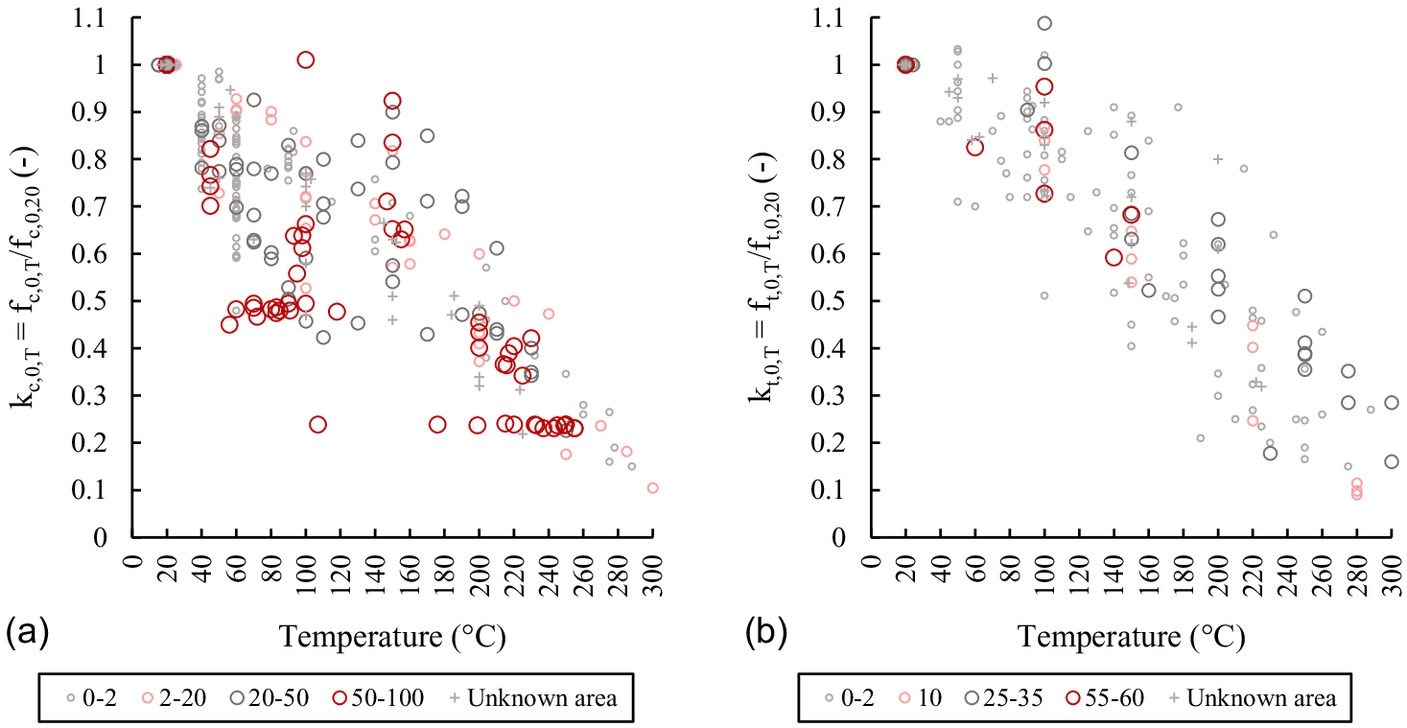

were collected from the literature review. Figs.

1 and

2 show the variability in the reduction of timber compressive and tensile strengths at high temperatures. Although 20°C is the commonly adopted value for ambient temperature (

CEN 2004c), the reason why the timber strength at ambient temperature has been referred to as

or

in this paper, experimental tests from the literature showed some dispersion in the reference ambient temperature from which the data were normalized.

Figs.

1 and

2 also include the deterministic reduction factor models of EN 1995-1-2 (

CEN 2004c) for timber strength parallel to grain. The Eurocode models appear conservative compared with the experimental data collected, especially in the case of compressive strength.

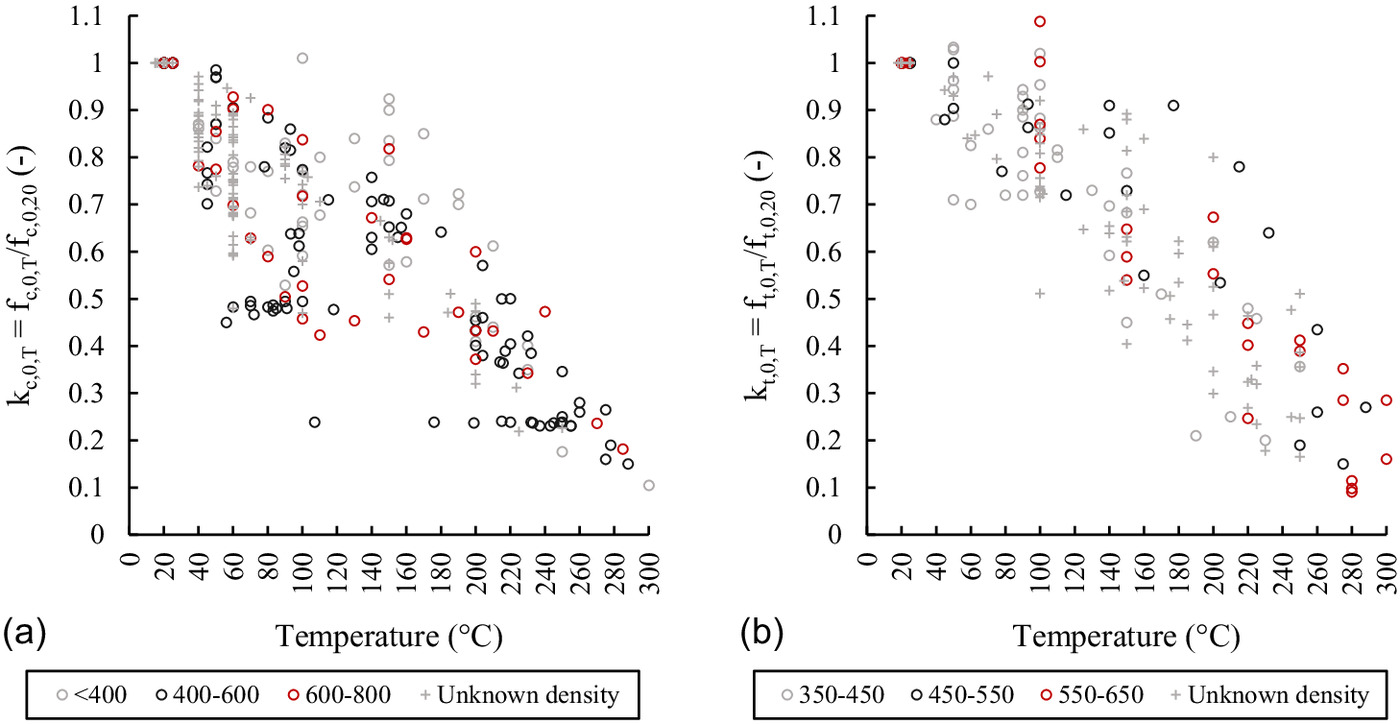

Next, the influence of specimen’s density, initial moisture content, and size on timber compressive and tensile strengths parallel to the grain at elevated temperatures was qualitatively analyzed. Such effects do not necessarily have to be manifested because the experimental data points are normalized by the strength at room temperature of specimens of similar characteristics. First, Fig.

3 shows the effect of the specimen density on

and

. The mean densities of compressive tests specimens ranged from 133 to

, and those of tensile strength varied between 347 and

. Even though timber strength tends to be higher as density increases (

CEN 2016), the strength reduction as a function of temperature did not seem to be governed by the density.

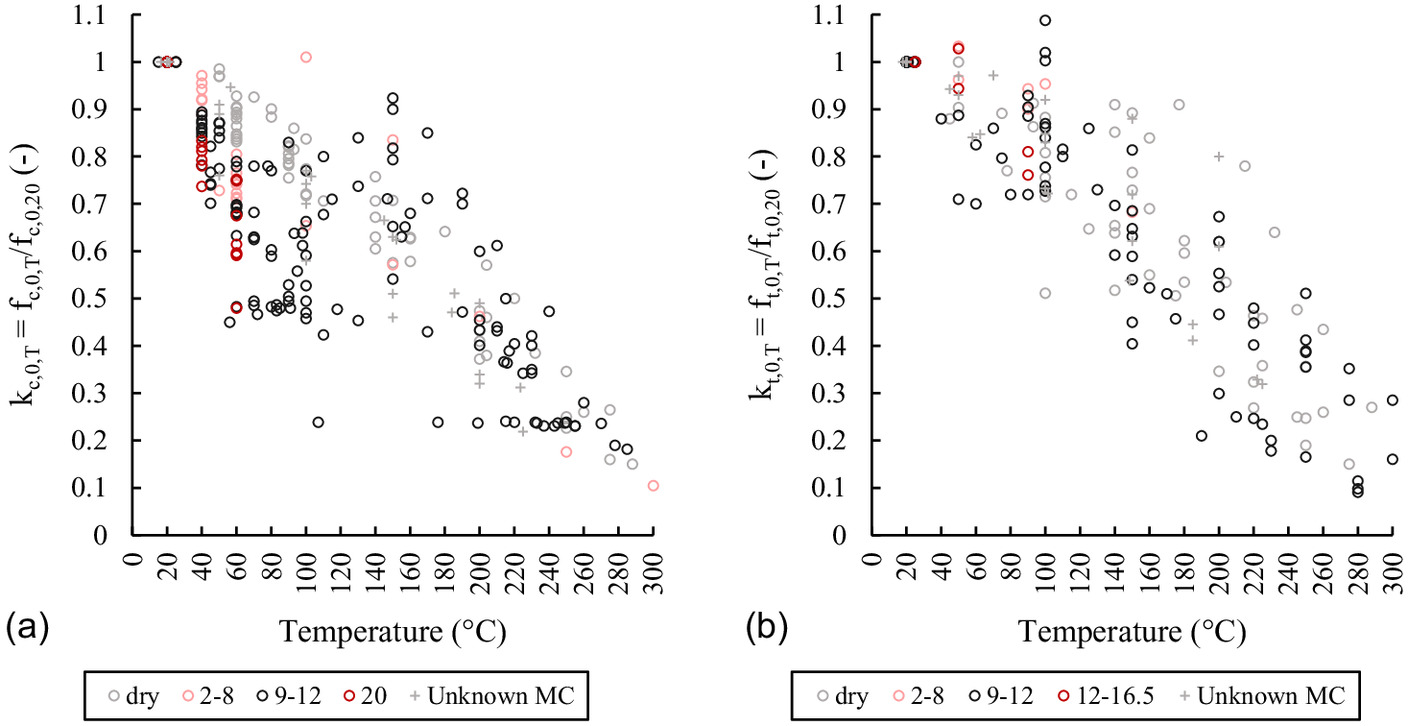

Fig.

4 shows the effect of the initial moisture content of the specimen on

and

. The collected data come from experimental tests performed mainly on dry specimens or with initial moisture contents of 9% to 12%. For compressive strength, the results at temperatures below 100°C showed that the higher the moisture content, the lower the value of

and thus the greater the reduction in strength.

For tensile strength, the experimental data were limited, and no obvious correlation was observed. This is in line with the findings of the literature review conducted by Gerhards (

1982), which reported, inter alia, that timber mechanical properties decreased with increasing moisture content and that temperature and moisture content appeared to have the least influence on timber tensile strength parallel to the grain compared with the results for other timber mechanical properties. Experimental data were limited above 100°C for specimens with initial moisture contents different from 9% to 12%, so limited observations could be made on the effect that different values of initial moisture content might have on timber strength above 100°C. However, some of the data from moist specimens showed an increase in timber compressive and tensile strengths from 100°C to reach a peak at around 150°C (

Do and Springer 1983;

Manríquez Figueroa and Dias De Moraes 2010,

2016;

Wiesner et al. 2021;

Zaben et al. 2020).

Several authors suggested that this increase in strength could be due to the reduction in moisture content as free moisture is driven off from wood (

Frangi et al. 2012;

Klippel et al. 2014;

Manríquez Figueroa and Dias De Moraes 2016), but the question of whether this strength increase occurs and, if so, how initial moisture content influences it, requires further research (

Buchanan and Abu 2017). In addition, moisture migration into the heated wood, whose gradients and thus effects will be greater in larger cross sections, could also significantly affect the experimental tests results. Due to the significant role that moisture content seems to play on timber strength at elevated temperatures, its interaction with temperature needs to be further investigated.

Finally, Fig.

5 shows the effect of the cross-sectional area of the specimen on

and

. The experimental data associated with larger cross sections are represented in the figure by larger circles. The cross-sectional areas of the specimens from the experimental tests found in the literature ranged from 0.23 to

for

and from 0.10 to

for

. Tensile tests were generally performed on specimens with smaller cross sections, and dimensions of the specimens for compressive tests are quite variable. Specimen size directly influences the time of exposure to heat to reach steady state conditions because thermal and moisture gradients will be higher in larger specimens.

According to Buchanan and Abu (

2017), larger timber members are more likely to fail at lower stresses compared with similar smaller members because the former will have a greater number of potential defects. These size effects are recognized in design codes (

CEN 2004b). However, the experimental data did not show clear correlation between the cross-sectional dimensions of the specimens and the timber strength reduction, so further research might be needed. In the case of

, many experimental data points from specimens whose cross-sectional areas were between 50 and

showed relatively high reductions of timber compressive strength at elevated temperatures. These data points are mainly the results of the experimental tests carried out by Wiesner et al. (

2021), which considered exclusively specimens of CLT, where the influence of adhesive and ply configuration plays an important role in timber strength, whereas the rest of the papers provided data from experimental tests performed on solid timber specimens.

Furthermore, except for the specimens from the experimental tests conducted by Klippel et al. (

2014), the aforementioned experimental tests performed on specimens with presence of knots or other defects are linked to the categories with the larger cross-sectional areas, varying between

(

Nielsen and Olesen 1982) and

(

Wiesner et al. 2021). Consideration of specimens with larger cross-sectional dimensions allows a better assessment of the influence of defects on timber strength because they will be present to a greater extent. Because multiple variables were involved in the experimental tests carried out by Wiesner et al. (

2021) and no additional experimental data were found from other sources, possible correlations concerning engineered timber systems cannot be confirmed at this point.

It is important to highlight that besides the cross-sectional area, the length of the specimens influences the timber compressive and tensile strengths parallel to grain (

Fryer et al. 2018;

Moshtaghin et al. 2016a;

Showalter et al. 1987;

Totsuka et al. 2022). In particular, several studies (

Moshtaghin et al. 2016b;

Showalter et al. 1987) proposed models to consider the size effects on timber tensile strength, which are based on the weakest link theory for brittle failures. However, the possible effect of the specimen length on the reduction of timber strength at elevated temperatures was not statistically significant in the data set collected in the present study.

In summary, the literature review revealed a lack of standardization in the testing methods of timber specimens at elevated temperatures. Great variability was found among experimental tests from different sources, especially in specimen dimensions, as well as heating and loading conditions. The lack of standardization, together with the large number of variables involved, limits our common understanding of the effect of elevated temperatures on timber strength. Because the experimental data collected are influenced by multiple variables and experimental conditions, the possible effect of a single variable on the reduction of timber strength at high temperatures cannot be discerned and, therefore, observations derived from Figs.

3–5 should be taken as indicative. Greater standardization is desirable. In the meantime, the data exhibit large scatter and currently adopted models such as Eurocode appear very conservative, especially in compression. This calls for a probabilistic approach to refine the evaluations of the structural fire response of timber structures.

Discussion

The proposed probabilistic models for

and

are, in essence, continuous and closed-form equations defining the temperature-dependent parameters of the Weibull PDFs. The simplicity of the proposed probabilistic models enable their simple implementation in a numerical code for modeling structures in fire. In future studies, the authors intend to implement the probabilistic timber material in the nonlinear finite-element software SAFIR (

Franssen and Gernay 2017) to conduct probabilistic fire risk analyses of timber structures. Monte Carlo simulations can be performed by randomly selecting quantiles of the strength distribution when running the thermal-structural analyses. The parameters defining the Weibull PDFs can be evaluated for the temperatures obtained from the thermal analysis at each time step using Eqs. (

567)–(8).

As already discussed, probabilistic models for the temperature-dependent strength of steel and concrete were recently proposed by Qureshi et al. (

2020). In their study, those authors observed that the 0.5 quantiles (median) of the collected data for concrete and steel agreed quite well with the deterministic EN 1992-1-2 (

CEN 2004a) and EN 1993-1-2 (

CEN 2005) models, respectively. However, in the case of timber strength, the EN 1995-1-2 (

CEN 2004c) model has turned out to be very conservative, especially for compressive strength at temperatures above 80°C (Fig.

11). This can be observed from the reduction factors of the EN 1995-1-2 (

CEN 2004c) model plotted in Fig.

10 when compared with the corresponding proposed Weibull PDFs distributions. In the case of compressive strength, the values of

of EN 1995-1-2 (

CEN 2004c) correspond to approximately the 0.0011, 0.0012, and 0.0004 quantiles of the proposed probabilistic model at 100°C, 200°C, and 280°C, respectively, whereas for tensile strength, the associated quantiles are 0.101, 0.115, and 0.040.

On the other hand, timber strength values for fire design of EN 1995-1-2 (

CEN 2004c) were not consistent with those proposed for concrete (

CEN 2004a) and steel (

CEN 2005). The latter assumed a value of design strength in fire that depends on the characteristic strength (i.e., fifth percentile value) at ambient temperature, whereas in the case of timber, it depends on the 20th percentile strength. This discrepancy has recently been examined to assess whether timber strength values for fire design are unconservative. Specifically, a study by Fahrni (

2021) concluded that the 20th percentile assumption leads to appropriate reliability levels and, compared with the fifth percentile, provides lower reliability scatter. However, these findings are based on the standard ISO 834 fire exposure and, according to Fahrni (

2021), the resulting reliability is significantly dependent on the fire exposure. Thus, further research would be advisable to ensure that the same reliability level is achieved in the fire design of timber structures under different fire exposures.

Regarding the trend of the timber strength reduction at elevated temperatures, as can be deduced from the 0.5 quantiles shown in Fig.

11, tensile strength showed an almost linear relationship in which the strength decreased as temperature increased. Compressive strength, in contrast, decreased rapidly in the temperature ranges from ambient temperature to 100°C and from 200°C to 300°C and considerably slower between 100°C and 200°C, approximately. As can be observed in Fig.

11, the probabilistic model proposed for compressive strength yielded values very close to zero when 300°C is reached. Although this is in accordance with the standard provisions (

CEN 2004c), experimental data appear to show that some strength is still retained at 300°C. This is particularly evident for

, which shows a wide scatter within the experimental data from 250°C to 300°C. However, due to the limited number of experimental data points around the charring temperature of wood, further research would be necessary to assess whether the assumption of neglecting the strength of timber above 300°C might be somewhat conservative.

In short, the proposed probabilistic models captured uncertainties in timber strength at elevated temperatures based on the experimental data collected from the literature. These robust models can be applied to the fire safety design of any timber structure to reach target reliability levels through a more realistic assessment, as well as to achieve more efficient and, therefore, cost-effective fire-resilient designs.