Available Information

In earthquake engineering of gas pipelines, there are essentially two categories of models for estimating potential seismic damage: empirical RR models (e.g.,

American Lifelines Alliance 2001;

Eidinger 2020;

FEMA 2012;

O’Rourke 2014) and numerical fragility models (e.g.,

Ashrafi et al. 2019;

Jahangiri and Shakib 2018;

Lee et al. 2016;

Tsinidis et al. 2020b;

Yoon et al. 2019). Empirical RR models are typically developed from observed damage to pipelines in past earthquakes and yield the average number of repairs per length of pipe,

. Given strong ground shaking, common practice is to assume that 80% of repairs corresponds to leaks, whereas 20% of repairs corresponds to breaks (

FEMA 2012;

Pineda-Porras and Najafi 2010;

De Risi et al. 2018) because repair records after earthquakes do not always provide enough information to distinguish between different damage states (

O’Rourke 2014). Therefore, the RR functions in Eq. (

6) can be expressed as

and

. In contrast, numerical fragility models are typically developed from finite-element simulations of gas pipelines subjected to a range of conditions and yield probabilities of damage state exceedance,

. While exceedance probabilities can be readily used to obtain the occurrence probability for a given damage state,

, these probabilities do not directly provide the expected

number of damage state occurrences along a pipeline. One way of potentially applying fragility models for regional seismic risk assessments is to model the occurrence of damage along the pipeline as a binomial process using segments of length equal to that used in the development of the fragility model. For example, 1-km-long pipelines were studied in Jahangiri and Shakib (

2018), and hence, the RR functions in Eq. (

6) might alternatively be expressed as

and

; however, this approach implies an upper limit of one repair per kilometer, which might be reasonable for some but not all values of PGV (e.g., Table

3 in

O’Rourke and Palmer 1996).

Similarly, there are both advantages and disadvantages to numerical fragility models. For example, they are directly applicable to gas pipelines (e.g., representative joint types, grades of steel, wall thicknesses, operating pressures) and distinguish directly between different degrees of seismic damage. Furthermore, they typically capture a variety of input pipeline attributes that may impact seismic performance. However, numerical fragility models may not be directly applicable to regional seismic risk assessments because the key output is exceedance probability instead of RR. Strictly speaking, while numerical fragility models are directly applicable to gas pipelines, each model is applicable only to the specific conditions for which the model was developed [e.g., in the case of Tsinidis et al. (

2020b), buried gas transmission pipelines that cross locations of vertical geotechnical discontinuities].

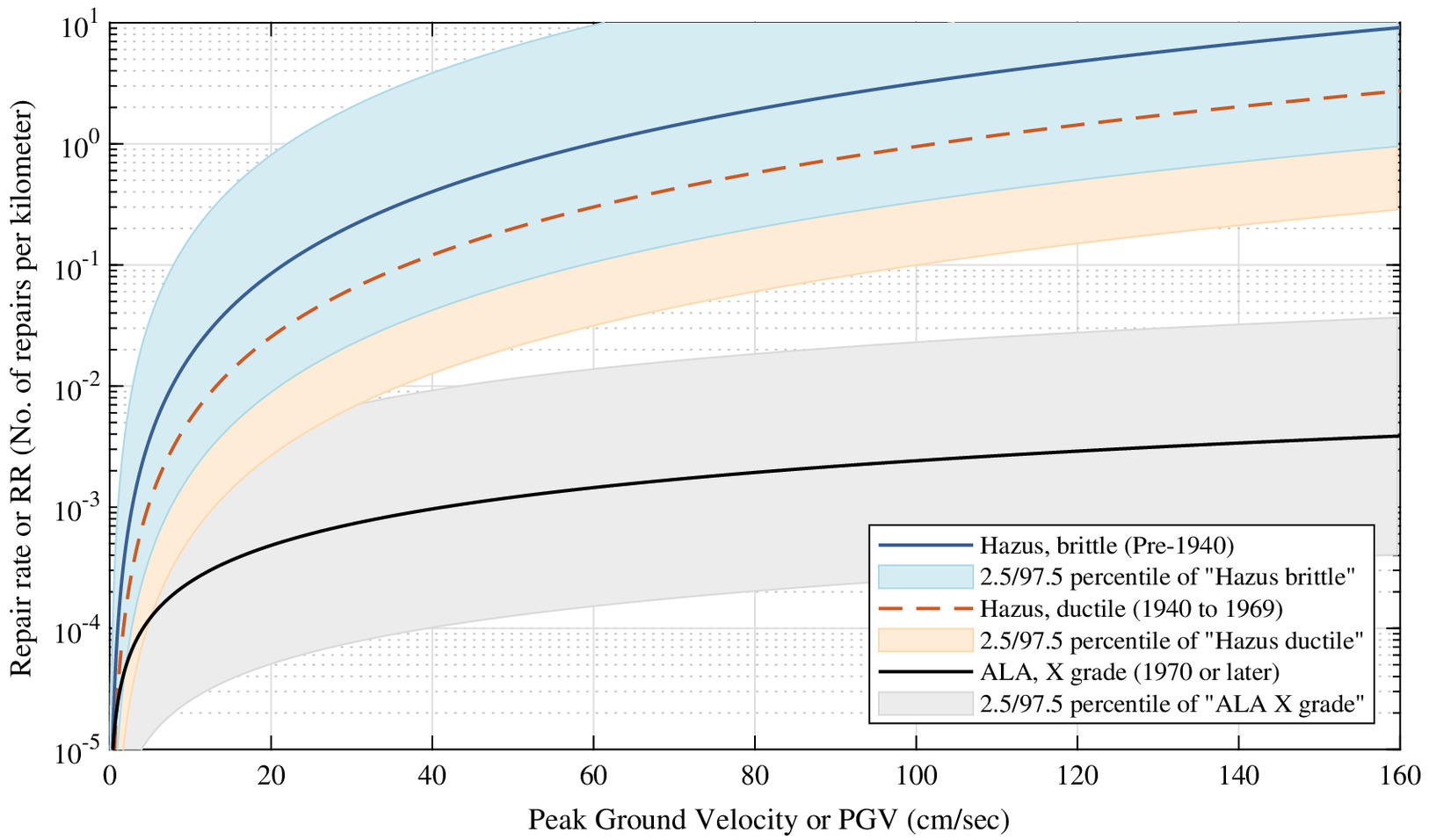

Given this context, we focus on two empirical RR models that have been accepted by the profession for regional seismic risk assessment of gas pipelines. The first model is the one that has been adopted into the Hazus methodology (

Esposito et al. 2015;

FEMA 2012;

Mousavi et al. 2014;

O’Rourke and Ayala 1993). In this model, the estimated RR is a function of pipeline ductility in addition to PGV. A “ductile” pipeline is defined in Hazus as one that is made of ductile material (e.g., steel with arc-welded joints), whereas other materials, including steel with gas-welded joints, are classified as “brittle” (page 8-17 in

FEMA 2012). The second model is the “X grade” version of the model by the

American Lifelines Alliance (ALA) 2001 [page 42 in American Lifelines Alliance (

2001)]. In this model, the RR function is based on the cast iron damage algorithm for unknown soil conditions but scaled by 0.01 to reflect the general quality controls and design procedures that are commonly used for gas pipelines. This X grade version is a function of PGV only and differs from the “welded steel” versions in Tables

4 and

5 of the same reference, which are intended for construction characteristics that are typical of water pipelines (

American Lifelines Alliance 2001).

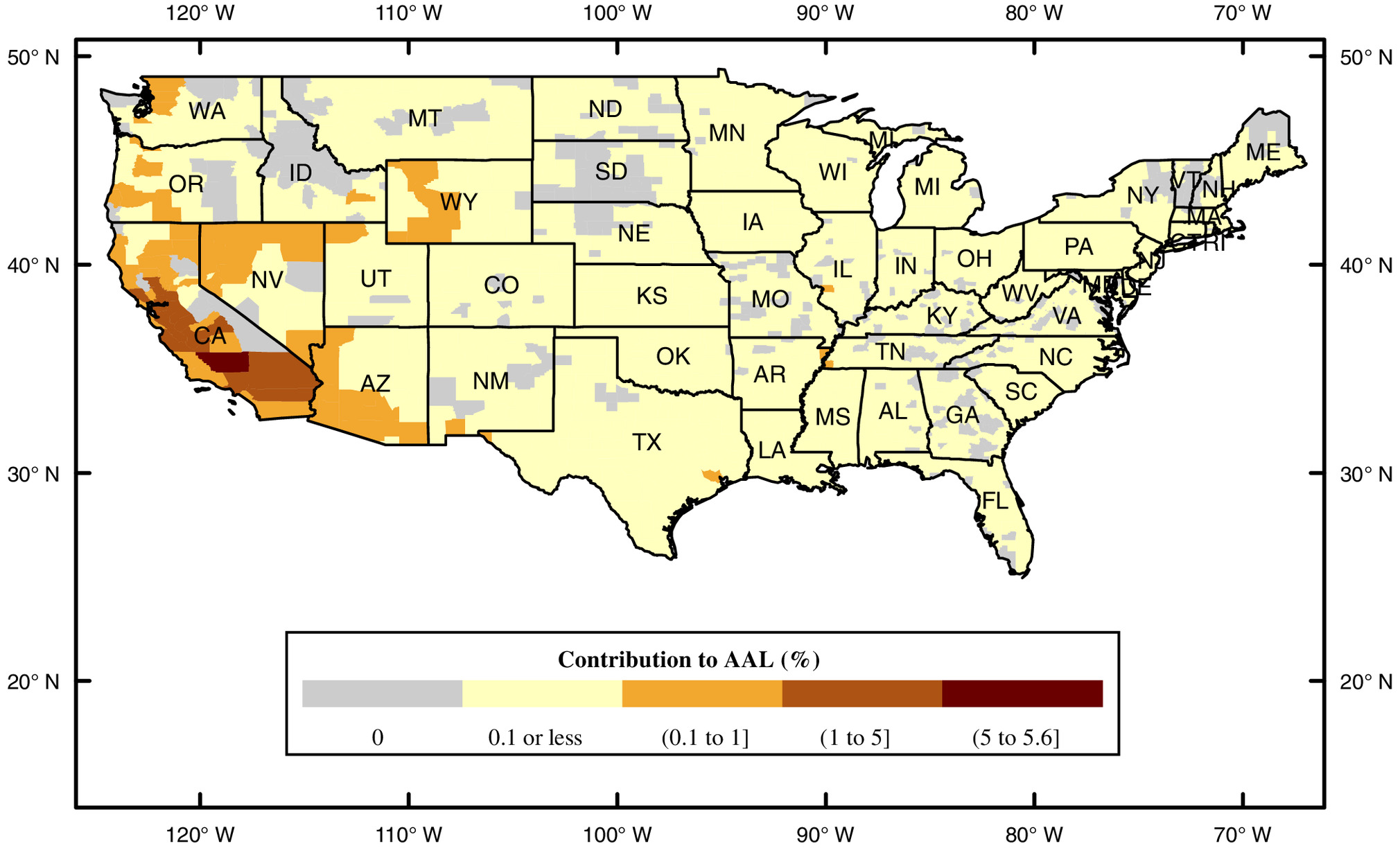

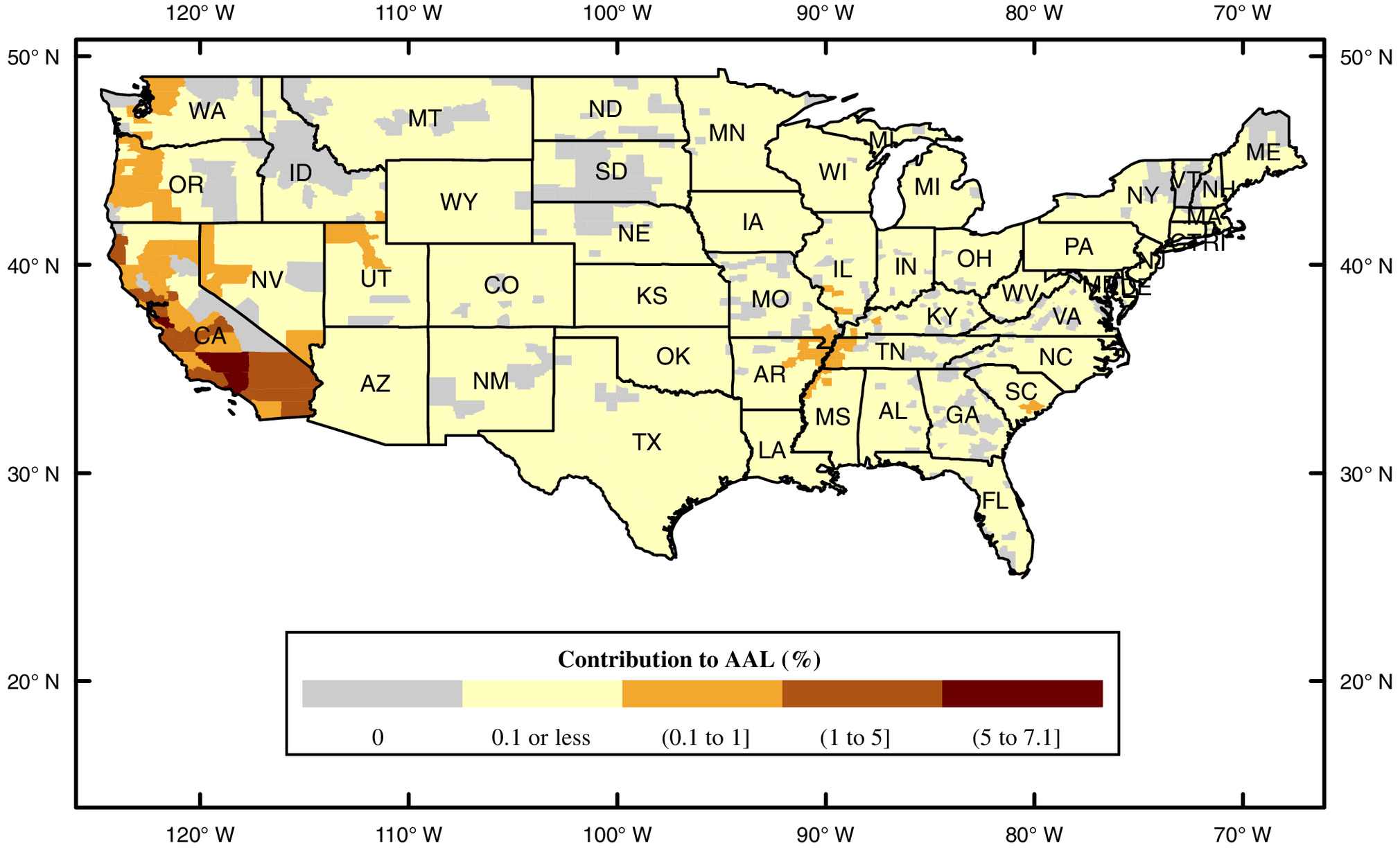

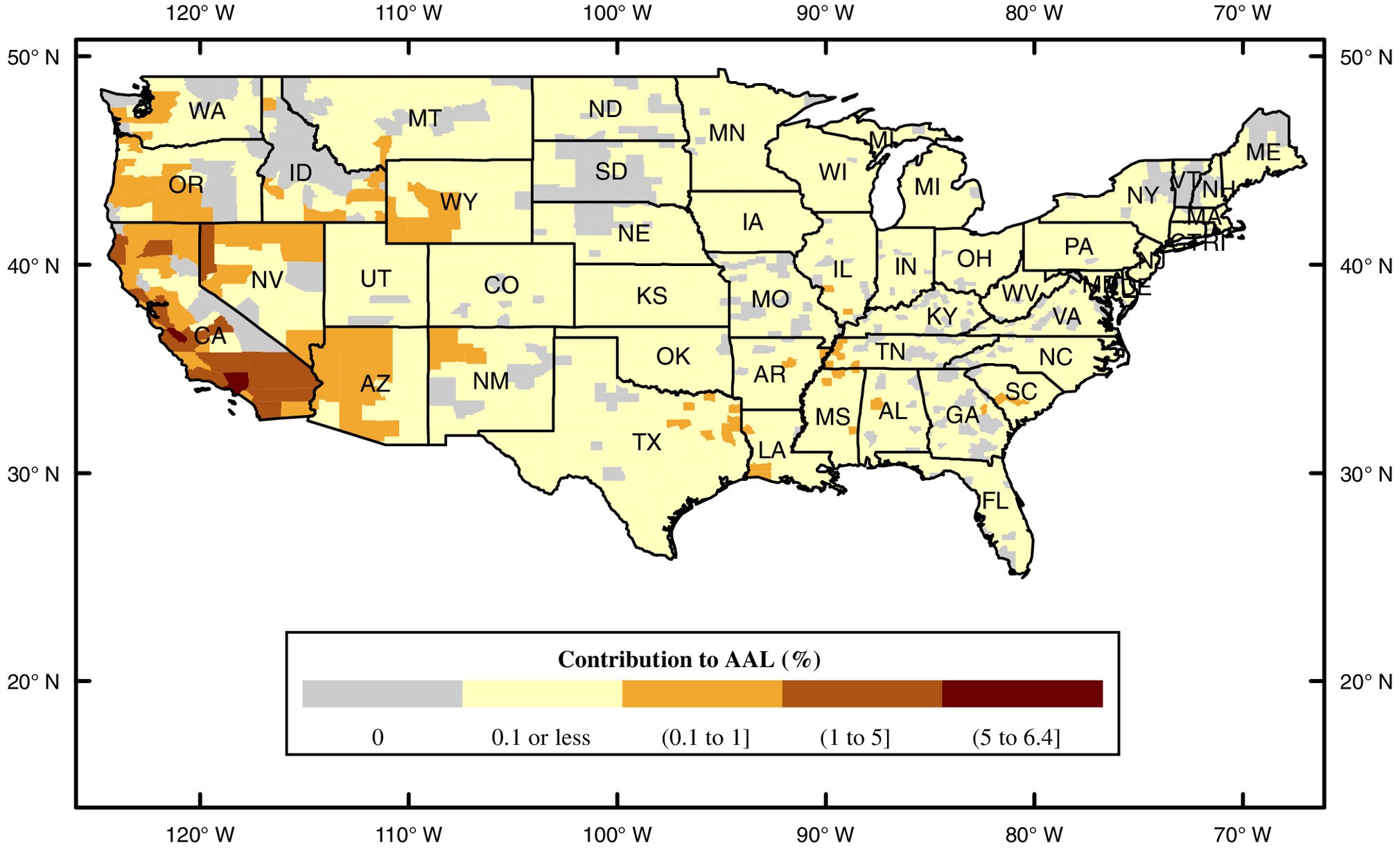

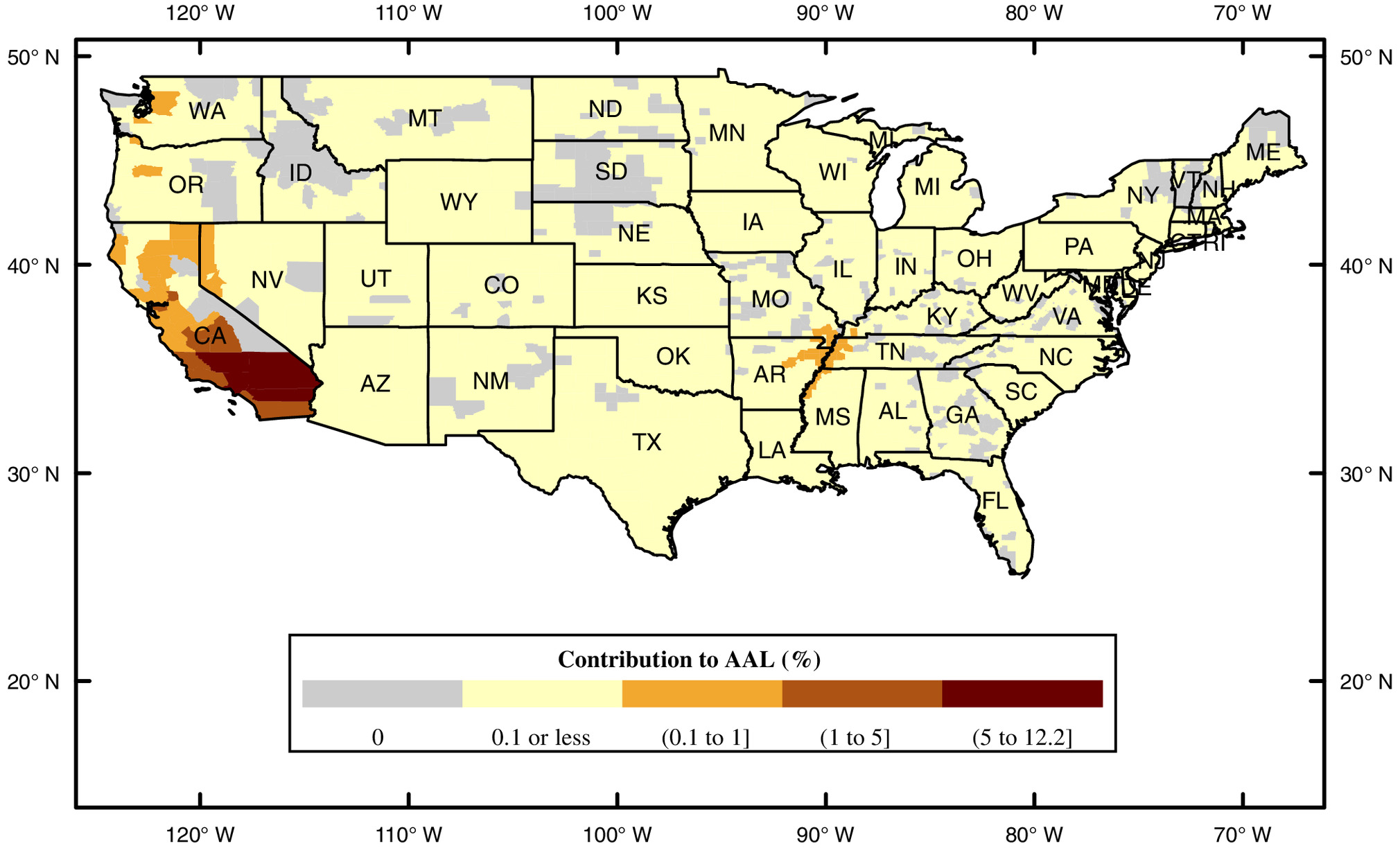

The preceding two empirical RR models are illustrated in Fig.

4. While the ductile curve from Hazus is lower than the brittle curve, it greatly exceeds the X grade curve from ALA. This level of difference highlights relatively large uncertainty in the estimated RR, even when both the level of PGV and the type of joint (e.g., not gas-welded) are known.

Empirical evidence for gas transmission pipelines suggests that both vulnerability models may be plausible. On the one hand, the Hazus model seems plausible because relatively high RRs have indeed been observed for gas transmission pipelines in past earthquakes. For example, Table

3 in O’Rourke and Palmer (

1996) shows that in areas with no reported permanent ground deformation during the 1994 Northridge earthquake, a RR of 0.27 repairs per kilometer was observed for Line No. 1001, which was installed in 1925, joined by oxy-acetylene welds, and damaged by transient ground deformations (

Honegger 2000). Similarly, the same table shows that in the 1971 San Fernando earthquake, a RR of 1.03 repairs per kilometer was observed for Line No. 102.90, which was installed in 1920–1921 and joined by oxy-acetylene welds. Using the USGS ShakeMaps (

Wald et al. 2005) for these two earthquakes as well as the approximate locations of these repairs depicted in Figs.

3 and

6 from O’Rourke and Palmer (

1996), a PGV range of 20 to

was estimated for the RR of 0.27, and a PGV range of 70 to

was estimated for the RR of 1.03, lending plausibility to both curves from Hazus.

On the other hand, the ALA X grade model also seems plausible because gas transmission pipelines have rarely been damaged by strong ground shaking in past earthquakes. For example, Table

3 in O’Rourke and Palmer (

1996) shows one instance of no damage in the 1933 Long Beach earthquake, five instances of no damage in the 1952 and 1954 Kern County earthquakes, one instance of no damage in the 1971 San Fernando earthquake, and three instances of no damage in the 1994 Northridge earthquake. Furthermore, unlike the gas distribution system (

Honegger 1998), the gas transmission system in San Francisco was virtually undamaged during the 1989 Loma Prieta earthquake (

National Research Council 1994, p. 140). Similarly, no leaks were found for gas transmission pipelines after the 2019 Ridgecrest earthquake sequence (

Jacobson 2019). These data lend plausibility to the X grade curve from ALA.

As noted on page 494 of O’Rourke and Palmer (

1996), in which the authors reviewed the earthquake performance of gas transmission pipelines over a period of 61 years, the higher incidence of oxy-acetylene weld damage is associated with the

construction quality (e.g., poor root penetration, lack of good fusion between pipe and weld), rather than the

type of weld (e.g., oxy-acetylene weld versus electric arc weld), although the two aspects are related (e.g., administering welds with an oxy-acetylene torch may cause poor construction quality). Consequently, we reviewed the literature on construction practices, revealing several key milestones that may impact the construction quality of gas transmission pipelines. For example, shielded-metal-arc welding started becoming the standard approach for joining pipes in the field around the 1930s, replacing acetylene girth welds (

Kiefner and Rosenfeld 2012, p. 29). Later, the time period of 1949 to 1962 was characterized by huge growth in pipe manufacturing, with new processes being developed and implemented. In 1955, the ASME standard B31 was revised, and for the first time, this revised ASME standard required recordkeeping of welding procedure qualification tests (

Rosenfeld and Gailing 2013, p. 13) and hydrostatic pressure testing of pipelines before their operation; however, no duration of the pressure testing was specified at that time (

Jacobs Consultancy Inc. and Gas Transmission Systems Inc 2013). In 1961, the CA Public Utilities Commission established state regulations (General Order 112) that required hydrostatic pressure testing of newly constructed pipelines for at least 1 h (

Rosenfeld and Gailing 2013). In 1970, the federal safety regulations for gas transmission pipelines were issued, setting minimum requirements for designing, constructing, operating, and maintaining gas transmission pipelines across the nation. These minimum requirements include additional recordkeeping beyond that for welding and hydrostatic pressure testing of newly constructed pipelines for at least 8 h. In summary, pipelines constructed since 1970 represent state of the art in metallurgy of steel, pipe mill practices, and construction techniques (

Kiefner and Trench 2001).

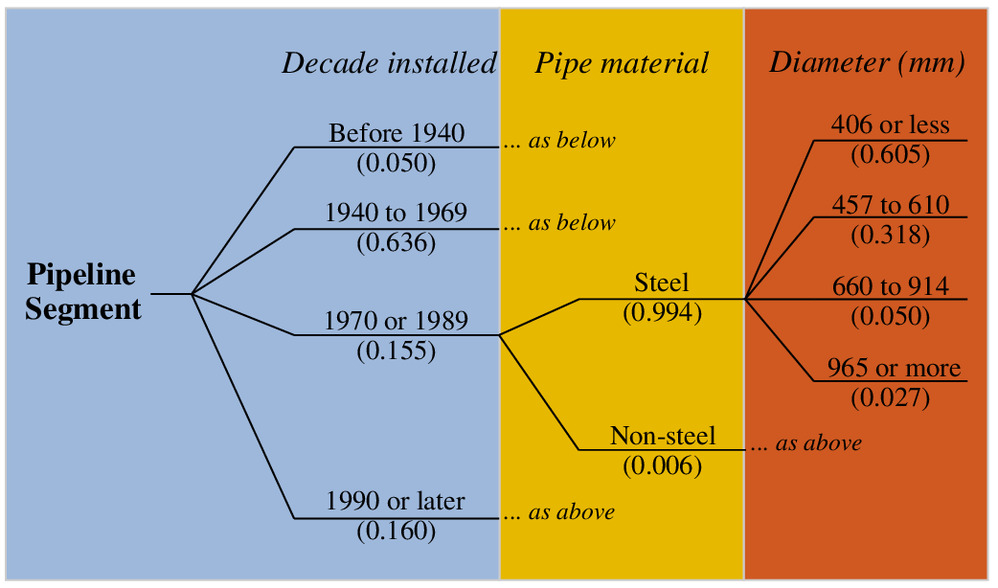

Given the plausibility of both vulnerability models and the preceding brief historical review of construction practices for gas transmission pipelines, we propose a third model that uses the pipeline segment’s decade of installation to combine existing models. Specifically, the brittle curve from Hazus is used for segments of pre-1940 vintage, whereas the X grade curve from ALA is used for segments that have been installed in 1970 or later; for the decades of installation between 1940 and 1969, the ductile curve from Hazus is used. When applying this proposed mixed model,

logic tree branches were considered for each pipeline segment to capture the decade of installation. Assuming 80% of repairs as leaks and 20% as breaks, these decade-dependent RR curves serve as best estimates of

and

in Eq. (

6). In passing, we note that a segment’s decade of installation is used as a proxy for quality of construction, not to convey that vulnerability depends on the segment’s age (

Kiefner and Rosenfeld 2012).

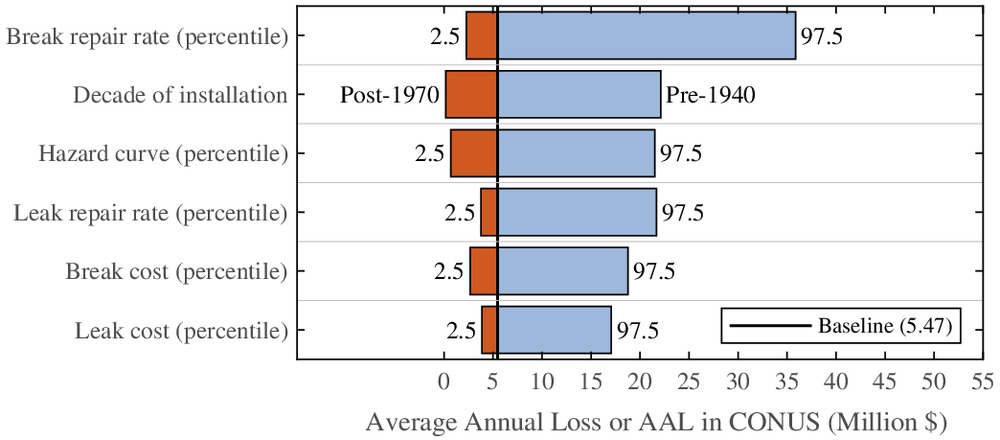

Uncertainty Analysis

The RR for leaks of a given pipeline segment

, with known PGV and known exposure, is denoted by

in Eq. (

6). The overall uncertainty in this RR arises from three underlying sources of uncertainty. First, it arises primarily from the functional relationship between the estimated RR and the input variables (i.e., PGV,

), or “model uncertainty” (

Kiureghian and Ditlevsen 2009). Because RRs are typically estimated from a regression model, this model uncertainty further consists of two components: uncertainty due to omitting input variables (e.g., omitting properties of surrounding soil when defining

for the vulnerability model) and uncertainty due to potentially inaccurate functional form (e.g., assuming a power law between PGV and RR). This model uncertainty can be viewed as partly epistemic because it can be reduced by employing more accurate functional forms in future models, but it can also be viewed as partly aleatory because our state of scientific knowledge may not allow refinement in functional form. Regardless of the categorization, this model uncertainty contributes to uncertainty in

, which propagates to uncertainty in the final AAL estimate.

Second, the overall uncertainty in

also arises from “parameter” (or statistical) uncertainty (

Kiureghian and Ditlevsen 2009). For example, even when the relevant input variables have been included and the functional form is known, uncertainty still exists in estimating the parameters for the functional form from limited data and this uncertainty propagates to uncertainty in the final AAL estimate. This parameter uncertainty can be viewed as epistemic because, in principle, the precision of parameter estimates increases with increasing data.

Third, the overall uncertainty in

arises from the assumed distribution of repairs as leaks (e.g.,

Bonneau and O’Rourke 2009, p. 113). Even when the vulnerability model for estimating RRs,

, is known with certainty (i.e., all input variables have been included, the accurate functional form was used, parameter estimates are precise), the uncertainty in distributing the repairs as leaks (i.e., 80% given strong ground shaking) propagates to uncertainty in the final AAL estimate. The categorization of this third source of uncertainty depends on whether the modeler foresees the potential for a reduction, but more importantly, this source of uncertainty also contributes to uncertainty in the final AAL estimate.

In this paper, the preceding three sources of uncertainty in are combined as a single uncertainty in “specification of the vulnerability model,” denoted by . For example, using is one modeling choice and using is another. Furthermore, utilizing the version of a model that has been updated with additional empirical data constitutes yet another choice in specification of the vulnerability model. Finally, the model uncertainty consists of specifying the input pipeline attributes that are relevant and specifying a functional form, which are both additional modeling choices. While the preceding discussion focused on leaks to identify the three underlying sources of uncertainty, it applies equally to breaks.

Unfortunately, no information is available to directly quantify each of the preceding underlying sources of uncertainty. Therefore, to estimate the uncertainty in

and in

, we assume a lognormal distribution for each RR. The corresponding medians are given by 80 and 20%, respectively, of the RR from the proposed mixed vulnerability model. Furthermore, their logarithmic standard deviations,

and

, are both assumed equal to 1.15, which is the model uncertainty for the backbone vulnerability model in ALA [Table 4-4 in American Lifelines Alliance (

2001)]. While this estimate of uncertainty may seem large, it is not unreasonably large because it excludes both parameter uncertainty and uncertainty in distributing repairs as leaks or breaks; moreover, it is within the range of estimates from other studies [see total uncertainties listed in Table D1 of Bellagamba et al. (

2019)]. Most importantly, this relatively large uncertainty is adopted herein to reflect the fact that even when a segment’s decade of installation is known, the resulting RR remains uncertain because it can conceivably be influenced by other input pipeline attributes (e.g., buried versus aboveground, diameter to thickness ratio, friction at soil-pipe interface, operating pressure, temperature). Fig.

4 illustrates this uncertainty using shaded regions that are defined by 2.5 and 97.5 percentiles of each empirical RR curve in the proposed mixed model.